SMO 254 | EN 1.4547

STAINLESS STEEL

SMO 254 | EN 1.4547

Description

Alloy SMO 254 is a high-alloy austenitic stainless steel that is highly resistant to corrosion, pitting, and crevice corrosion. It is also known as 6Mo or 1.4547. This alloy contains high levels of chromium, molybdenum, and nitrogen, which give it excellent resistance to a wide range of corrosive environments, including seawater, sulfuric acid, and hydrochloric acid.

SMO 254 is typically used in applications where corrosion resistance is critical, such as chemical processing, offshore and marine environments, and the pulp and paper industry. Its resistance to chloride-induced stress corrosion cracking makes it a popular choice for use in seawater applications.

In addition to its excellent corrosion resistance, SMO 254 has other beneficial properties, including high strength, good ductility, and excellent toughness. Its high nitrogen content also provides enhanced resistance to intergranular corrosion, which can be a concern in some high-temperature applications.

Alloy SMO 254 is a highly corrosion-resistant stainless steel alloy that offers excellent strength, toughness, and ductility. It is widely used in demanding applications where corrosion resistance is critical, such as chemical processing, offshore and marine environments, oil refinery, and the pulp and paper industry.

Raykam Alloys LLP is a reputed supplier, exporter, manufacturers and stockist of SMO 254 Grade raw materials. We cater our customers globally with high quality materials, timely deliveries and competitive rates. Superior quality and customer satisfaction are always a priority for us.

Applications of SMO 254

- Chemical processing and storage equipment

- Oil and gas production and processing

- Desalination and other seawater applications

- Pulp and paper processing equipment

- Food processing and storage equipment

- Pharmaceutical and biotech processing equipment

- Power generation and heat exchangers

- Pollution control equipment

- Mining and metallurgical processing equipment

- Aerospace and defense components

- Marine and offshore applications, including seawater handling systems, offshore platforms, and subsea pipelines

- Heat exchangers and condensers for cooling and heating applications

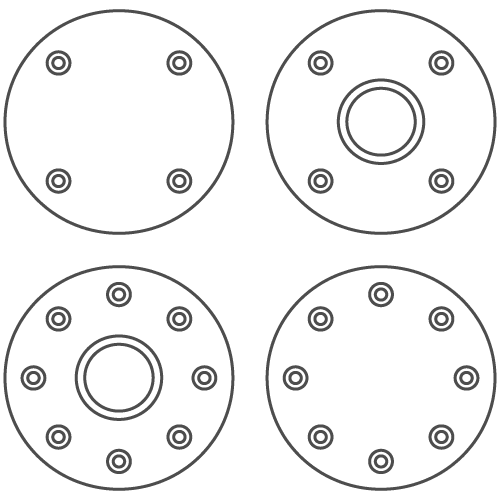

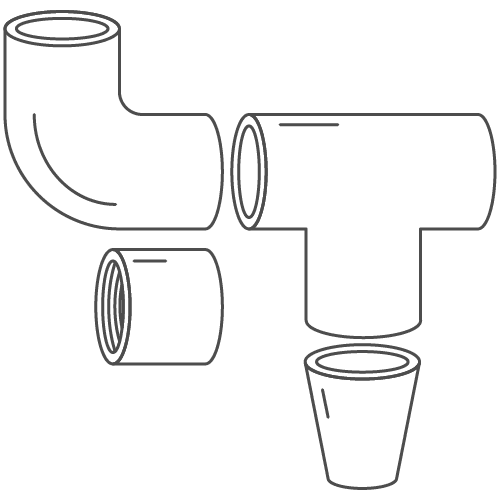

Available Forms