NICKEL ALLOY FLANGES

Raykam Alloys LLP offer a wide range of grades for High-Quality Prime Stainless Steel Coils with EN 3.1 Certified Test Certificates and Dual Certifications as per the customer's requirements. Raykam Alloys LLP being a Leading Stockist of Stainless Steel Coils deals in a wide range of sizes and dimensions. We deal in standard sizes as well as make to order custom sizes with reasonable MOQ.

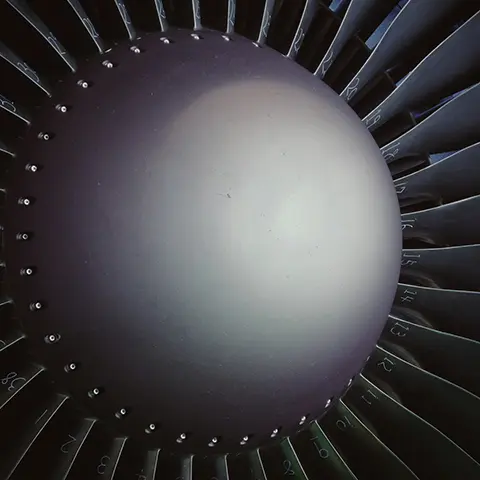

Nickel alloy flanges are specialized types of flanges made from alloys containing a high proportion of nickel. These flanges are designed to provide exceptional strength, corrosion resistance, and durability in extreme environments such as high-temperature, high-pressure, and corrosive applications. Raykam Alloys LLP supplies Nickel Alloy Flanges as per the desired standard by the customer, including ANSI/ASME B16.5, ANSI/ASME B16.47, ASTM B564, ASTM B462, MSS SP-43, MSS SP-44, API 6A, ISO 7005-1, DIN 2633, EN 1092-1 and many more.

Nickel alloy flanges are available in a variety of shapes and sizes, including weld neck, slip-on, threaded, lap joint, and blind flanges. They are commonly used in industries such as chemical processing, oil and gas, petrochemical, and power generation.

The most commonly used nickel alloys for flange production are Inconel, Monel, and Hastelloy. Inconel is a family of nickel-chromium-based superalloys that offer excellent resistance to high temperatures, oxidation, and corrosion. Monel is a nickel-copper alloy that provides superior resistance to acids, salts, and seawater. Hastelloy is a nickel-molybdenum-chromium alloy that offers excellent resistance to a wide range of corrosive environments.

Nickel alloy flanges are manufactured using various methods, including forging, machining, and casting. The manufacturing process depends on the type of nickel alloy being used, the size and shape of the flange, and the specific application requirements.

In addition to their high-performance characteristics, nickel alloy flanges also offer several benefits over traditional flanges. For example, they can withstand high temperatures and pressures without losing their strength or integrity. They also provide excellent resistance to corrosion, which reduces the need for frequent maintenance and replacement.

Nickel alloy flanges are critical components in many industrial applications that require high performance, durability, and resistance to extreme environments. Their specialized properties and construction make them ideal for use in demanding applications where other materials may fail.

Raykam Alloys LLP is a reputed name for global exports of Stainless Steel Coils. We offer EXW, FOB, CIF quotes for all our products with ready to dispatch planning. All of our materials come with a test certificate and inspection report to assure our customers that they are receiving what they are ordering. We believe in building a long lasting relationship with our clients.

NICKEL ALLOY FLANGES GRADES WE OFFER

We offer a wide range of Nickel Alloys Flanges grades with EN 3.1 Certified Test Certificates and Dual Certifications as per the customer's requirements. Raykam Alloys excels in all of the following Nickel Flanges grades types: Inconel, Monel, Hastelloy, Waspaloy, Nimonic, Haynes, Alloy X, and many more . A wide range of grades, sizes and dimension of all the Nickel Alloys Flange categories is what makes us one of the top Stockists of India. Explore our wide range of Inconel, Monel, Hastelloy, Waspaloy, Nimonic, Haynes, Alloy X, and many more types below in our professionally managed Nickel Alloy Flanges Grades Chart.

NICKEL ALLOY FLANGES GRADES LIST

| ASTM | EN | AISI | DIN | IS | UNS |

|---|---|---|---|---|---|

| Alloy 200 | 2.4066 | Nickel 200 | Ni99.6 | - | N02200 |

| Alloy 201 | 2.4068 | Nickel 201 | Ni99 | - | N02201 |

| Alloy 270 | 2.4050 | Nickel 270 | Ni99.8 | - | N02270 |

| Alloy 400 | 2.4360 | Monel 400 | NiCu30Fe | - | N04400 |

| Alloy K-500 | 2.4375 | Monel K-500 | NiCu30Al | - | N05500 |

| Alloy 75 | 2.4630 | Nimonic 75 | NiCr20Ti | - | N06075 |

| Alloy 600 | 2.4816 | Inconel 600 | NiCr15Fe | - | N06600 |

| Alloy 625 | 2.4856 | Inconel 625 | NiCr22Mo9Nb | - | N06625 |

| Alloy 90 | 2.4632 | Nimonic 90 | NiCr20Co18Ti | - | N07090 |

| Alloy C-263 | 2.4650 | Nimonic C-263 | NiCo20Cr20MoTi | - | N07263 |

| Alloy 718 | 2.4668 | Inconel 718 | NiCr19NbMo | - | N07718 |

| Alloy X-750 | 2.4669 | Inconel X-750 | NiCr15Fe7TiAl | - | N07750 |

| Alloy 800H | 1.4958 | Incoloy 800H | X5NiCrAlTi31-20 | - | N08810 |

| Alloy 800HT | 1.4959 | Incoloy 800HT | X8NiCrAlTi32-21 | - | N08811 |

| Alloy 825 | 2.4858 | Incoloy 825 | NiCr21Mo |

- | N08825 |

| Alloy 901 | 2.4975 | Nickel 901 | NiFeCr12Mo | - | N09901 |

| Alloy C-276 | 2.4819 | Hastelloy C-276 | NiMo16Cr15W | - | N10276 |

| XM-19 | 1.3964 | Nitronic 50 | X2CrNiMnMoNNb21-16-5-3 | - | S20910 |