AISI 409 | EN 1.4512

STAINLESS STEEL

AISI 409 | EN 1.4512

Description

Grade 409 stainless steel is a Ferritic steel that offers good mechanical properties and high-temperature corrosion resistance. It is commonly considered as a chromium stainless steel, with applications in exhaust systems of automobiles and applications that demand weldability. It has excellent oxidation and corrosion resistance qualities, and also showcases excellent fabricating characteristics, which allow it to be formed and cut easily.

It typically has one of the lowest price-points of all the types of stainless steel. It has decent tensile strength and is readily welded by arc welding as well as being adaptable to resistance spot and seam welding. The higher Manganese version of the alloy is 409M. It is reasonable to expect specifications in these standards to be similar but not necessarily identical to those given in this data sheet.

Applications of 409

- Automotive exhaust systems

- Industrial equipment (heat exchangers, boilers, furnace components)

- Architectural applications (building facades, handrails, decorative features)

- Kitchen equipment (sinks, countertops, appliances)

- Material handling (conveyor belts, rollers)

- Mining equipment (crushers, screens)

- Petrochemical processing (piping, storage tanks)

- Medical equipment (surgical instruments, medical implants)

- Aerospace and aviation (jet engine components)

- Marine applications (boat fittings, marine structures)

- Food processing (conveyors, mixing tanks)

- Power generation (turbine blades, exhaust systems)

- Chemical processing (reactors, storage tanks)

- Fuel Filters

- Agricultural machinery

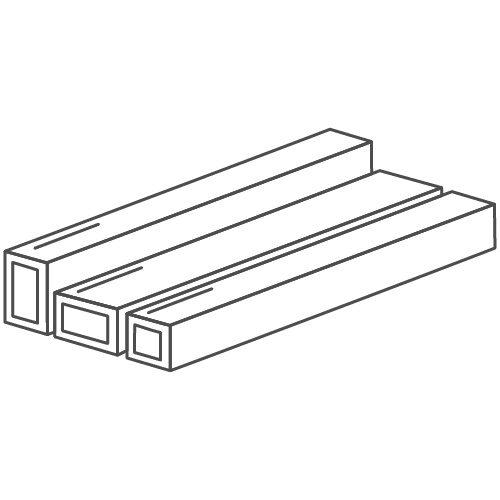

Available Forms