Nimonic 90 | EN 2.4632

NICKEL ALLOYS

Nimonic 90 | EN 2.4632

Description

Nimonic 90 is a Nickel-Chromium-Cobalt alloy being precipitation hardenable, having high stress-rupture strength and creep resistance at high temperatures up to about 950°C. It is widely used and a well proven alloy in high temperature conditions. It's derived strength is due to the addition of aluminium and titanium in the alloying process. The material offers good resistance to high-temperature corrosion and oxidation. The alloy is also known as Superimphy 90, Pyromet 90, and Udimet 90.

Applications of Nimonic 90

- Turbine Blades

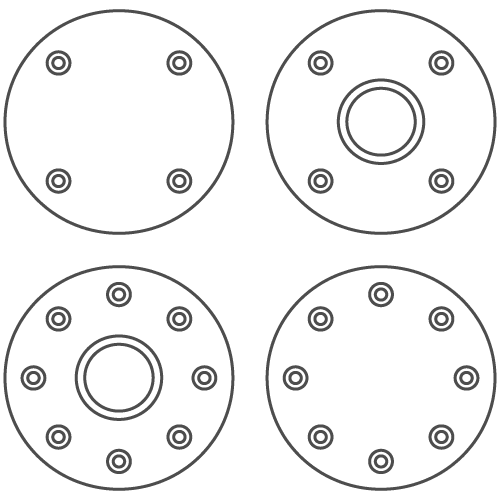

- Discs

- Forgings

- Ring Sections

- Hot-Working Tools

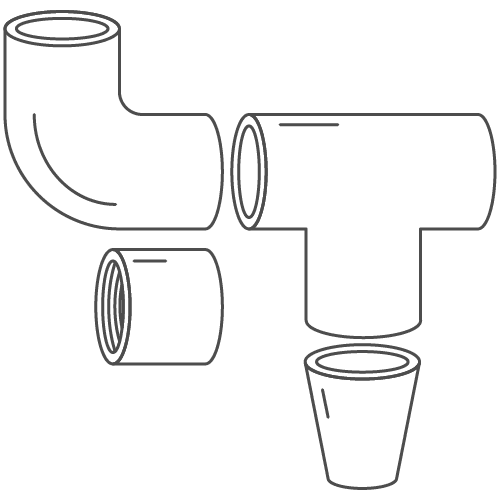

- Pressure Cessels

- Aircraft Structures

- Jet engine components

- Gas turbines

- Steam turbines

- Heat exchangers

- Reactors

- Offshore platforms

- Refineries

- Petrochemical plants

- Chemical pipelines

- Automotive exhaust systems

- Industrial furnaces

- Flue gas systems

- Power plant boilers

- High-temperature valves

- Incineration plants

- Steam systems

- Thermal power plants

- Heat treatment processes

- High-pressure steam lines

- Hydrocarbon processing plants

Available Forms