Incoloy 825 | EN 2.4858

NICKEL ALLOYS

Incoloy 825 | EN 2.4858

Description

Incoloy 825 is highly resistant to corrosion. It has a high nickel content, sufficient to resist chloride ion stress corrosion cracking, and a very stable austenite structure. The levels of molybdenum and copper enable the alloy to resist reducing agents and acids. Chromium gives resistance to oxidising conditions, such as nitric acid solutions, nitrates and oxidising salts. The alloy is titanium stabilised to resist pitting and intergranular attack after fabrication, particularly welding, which includes heating in the critical sensitisation temperature range (650°C – 760°C).

Alloy 825 offers exceptional resistance to corrosion by sulphuric and phosphoric acids and is often the most cost effective alloy in sulphuric acid service.

Applications of Incoloy 825

- Sulphuric Acid Piping and Cessels

- Phosphoric Acid Evaporators

- Pickling Tank Heaters, Pickling Tanks and Equipment

- Chemical Process Equipment

- Propellor Shafts

- Tank Trucks

- Calorifiers

- Electrostatic Precipitator Electrodes

- Hot Vessels for Food, Water and Seawater

- Ammonium Sulphate Vessels

- Expansion Bellows

- Marine Exhaust Systems

- Power Station Ash Hoppers

- Chemical processing plants

- Oil and gas exploration and production

- Desalination plants

- Marine and offshore applications

- Power generation

- Pharmaceutical manufacturing

- Waste treatment facilities

- Petrochemical industries

- Food and beverage processing

- Pulp and paper mills

- Heat exchangers

- Reactors and pressure vessels

- Water treatment plants

- Fertilizer production

- Semiconductor manufacturing

- Mining and metallurgical processes

- Cryogenic storage and transportation

- Hydrocarbon processing

- Nuclear power plants

- Air pollution control systems

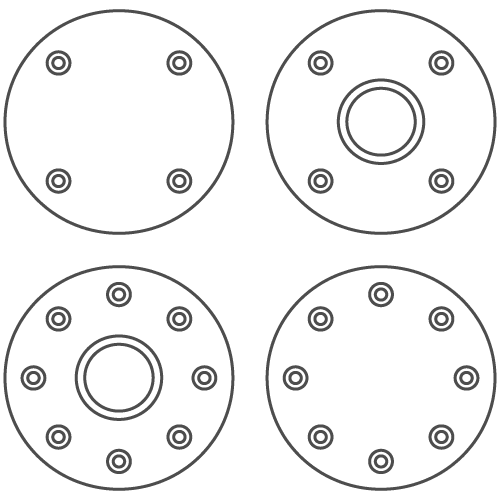

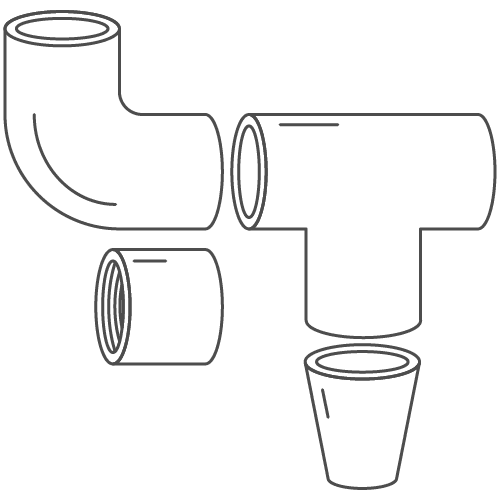

Available Forms