Incoloy 800HT | EN 1.4959

NICKEL ALLOYS

Incoloy 800HT | EN 1.4959

Description

Incoloy 800HT Nickel-Chromium-Iron alloy has the same basic composition as Incoloy 800, but has significantly higher creep rupture strength, resultant from the close control of the carbon, aluminium and titanium contents. It has good strength and excellent resistance to oxidation and carburisation in high temperature atmospheres. It also resists corrosion in many aqueous environments.

Applications of Incoloy 800HT

- Heat Exchangers and Process Piping

- Pressure Vessels

- Super-Heater And Re-Heaters in Power Plants

- Electric Range Heating-Element Sheathing

- Chemical and Petrochemical Processing

- Heat-Treating Equipment

- Ethylene furnace quench boilers

- Hydrocarbon Cracking

- Valves, Fittings and Other Components Exposed to Corrosive Attack from 600-1000° C Industrial Furnaces

- Chemical processing

- Petrochemical industry

- Power generation plants

- Furnace components

- Aerospace industry

- Nuclear power plants

- Heat exchangers

- Thermal processing equipment

- Refineries

- Offshore platforms

- Steam boilers

- Superheaters

- Turbine connections

- Combustion chambers

- Exhaust systems

- Reactor coolant systems

- Steam generators

- Annealing furnaces

- Industrial ovens

- Heat-treating systems

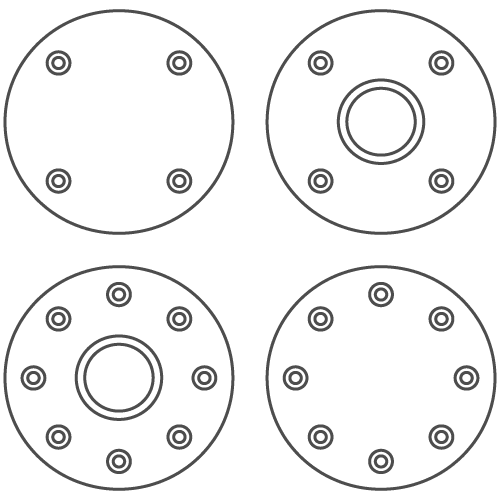

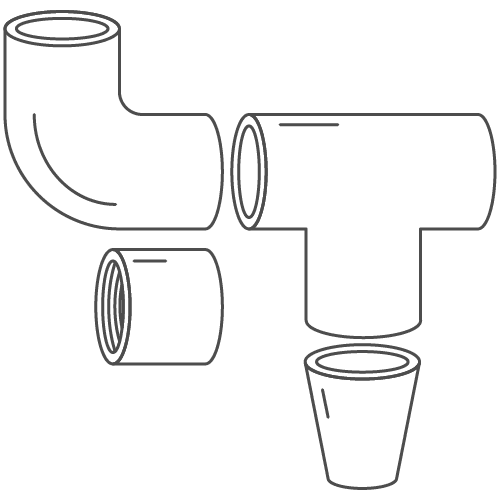

Available Forms