Nickel 201 | EN 2.4068

NICKEL ALLOYS

Nickel 201 | EN 2.4068

Description

Nickel 201 alloy is a commercially pure wrought alloy having properties similar to that of Nickel 200 alloy, but with a lower carbon content to avoid embrittlement by inter-granular carbon at high temperatures. Lower carbon content also reduces hardness, which makes it ideally suited for spinning and cold forming. The metal showcases good magnetostrictive properties. The alloy also displays High electrical and thermal conductivity with Good ductility and low work hardening rate. It also has good weldability and solderability. It is resistant to acids and alkalis, and dry gases at room temperature. It is also resistant to mineral acids depending on the temperature and concentration of the solution.

Applications of Nickel 201

- Caustic Evaporators

- Combustion Boats

- Electronic Components

- Plater Bars

- Manufacture and handling of sodium hydroxide, particularly at temperature above 300C

- Production of viscose rayon

- Manufacture of soap

- Analine hydrochloride production and in the chlorination of aliphatic hydrocarbons such as benzene, methane and ethane

- Manufacture of vinyl chloride monomer

- Reactors and vessels in which fluorine is generated and reacted with hydrocarbons

- Chemical processing

- Aerospace

- Power generation

- Nuclear

- Oil and gas

- Marine

- Electronics

- Food processing

- Pharmaceutical

- Pulp and paper

- Pollution control

- Heat exchangers

- Cryogenic applications

- Seawater desalination

- Welding electrodes

- Electroplating

- Battery components

- Medical equipment

- High-pressure piping systems

- Cryogenic storage vessels

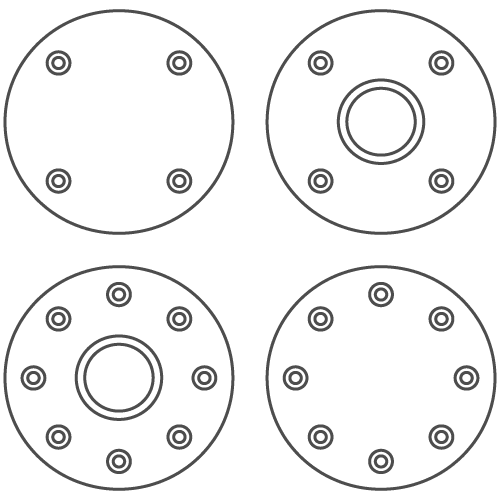

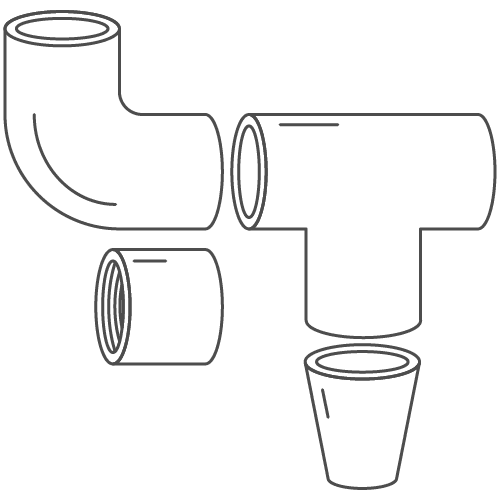

Available Forms