Inconel X-750 | EN 2.4669

NICKEL ALLOYS

Inconel X-750 | EN 2.4669

Description

Inconel X-750 is a Nickel-Chromium alloy made precipitation hardenable by additions of Aluminium and Titanium, having creep-rupture strength at high temperatures to about 700°C. It is widely used for high temperature conditions but is not as strong as Nimonic 90, but the alloy also holds exceptional properties all the way down to cryogenic temperatures. The alloy is highly resistant to chemical corrosion and oxidation and has high stress-rupture.

Applications of Inconel X-750

- Aerospace engines

- Gas turbine systems

- Oil refineries

- Chemical processing plants

- Power plant boiler systems

- Heat exchangers

- Offshore drilling rigs

- Subsea equipment

- Nuclear power plants

- Desalination plants

- Automotive exhaust systems

- Turbochargers

- Pharmaceutical reactors

- Cryogenic storage facilities

- Research laboratories

- Sterilizers

- Petrochemical storage tanks

- Aircraft ducting

- LNG (liquefied natural gas) applications

- Hydrogen production facilities

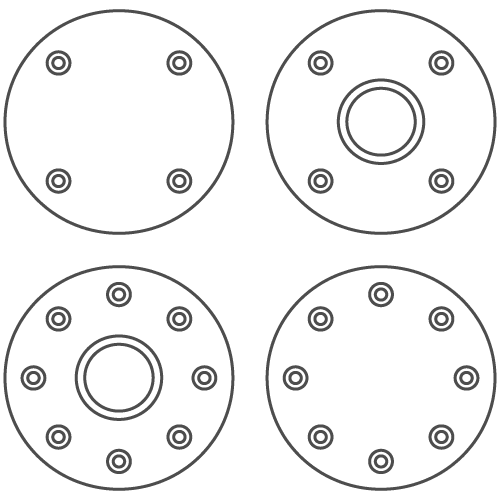

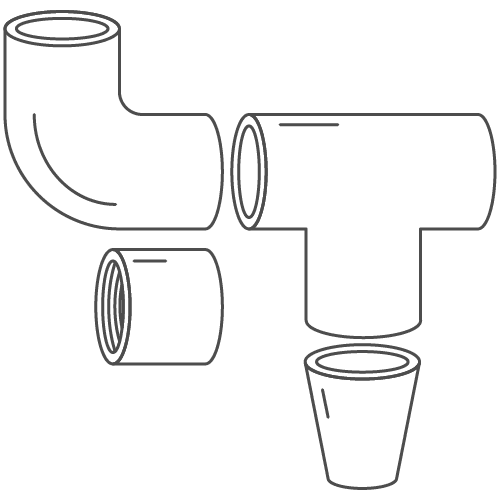

Available Forms