Nimonic 75 | EN 2.4630

NICKEL ALLOYS

Nimonic 75 | EN 2.4630

Description

Nimonic 75 is a Nickel-Chromium alloy with good corrosion and heat resistance, and contains Titanium and Carbon as additives. The alloy has good mechanical properties and oxidation resistance at elevated temperatures. The alloy is strengthened by the addition of titanium. Initially used as turbine blades in the 1940s, It is readily fabricated and welded. The alloy is also known as Nicrofer 7520.

One of the standout features of Nimonic 75 is its impressive resistance to high temperatures. This characteristic makes it a valuable asset in industries such as aerospace and gas turbines, where components are exposed to extreme heat. The alloy's remarkable stability at elevated temperatures contributes to its longevity and reliability in these challenging environments, making it suitable for applications in Equipments, Core Reactors, Piping Solutions, Marine Applications and many more.

Applications of Nimonic 75

- Gas Turbine Engines

- Industrial Furnaces

- Nuclear Engineering

- Aerospace Fasteners

- Aerospace engines

- Gas turbines

- Aircraft engine components

- Power generation (gas and steam turbines)

- High-pressure steam lines

- Heat exchangers

- Chemical processing plants

- Reactors

- Distillation columns

- Piping systems for corrosive fluids

- Oil and gas production equipment

- Wellheads

- Christmas trees

- Manifolds

- Valves

- Offshore and onshore environments

- Automotive exhaust systems

- Turbochargers

- High-performance engine components

- Thermal processing equipment

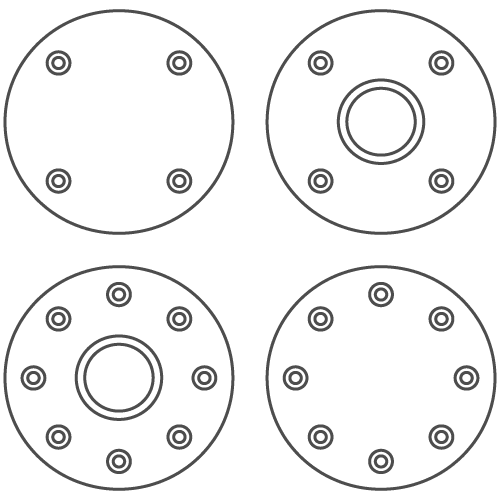

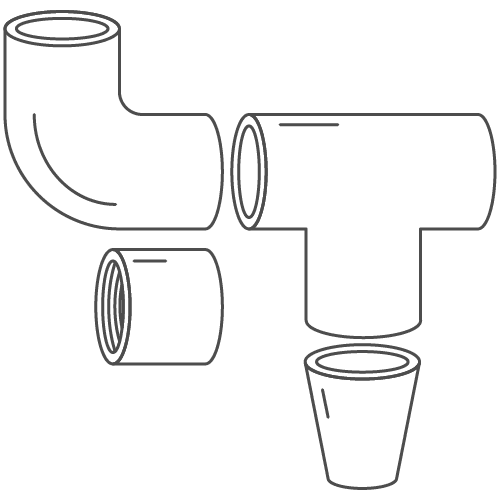

Available Forms