Haynes 188 | EN 2.4683

NICKEL ALLOYS

Haynes 188 | EN 2.4683

Description

Raykam Alloys LLP, a distinguished name in the world of advanced alloys and materials is a stockist and supplier of HAYNES® 188 alloy, a premium cobalt-nickel-chromium-tungsten alloy that redefines high-temperature performance. With decades of expertise in delivering top-quality materials, Raykam Alloys LLP stands as a trusted manufacturer and supplier of HAYNES® 188 alloy, catering to the stringent demands of industries across the globe.

HAYNES® 188 alloy boasts remarkable high-temperature strength, making it an optimal choice for applications where reliability under extreme conditions is paramount. With its robust cobalt-based composition, this alloy excels in maintaining its structural integrity even at temperatures exceeding 2000°F (1095°C).

Thermal stability is a hallmark of excellence for alloys intended for prolonged high-temperature use. While HAYNES 188 alloy shares similarities with solid-solution-strengthened superalloys like alloy 625 or HASTELLOY X alloy, its behavior is notably improved. It's essential to mention that HAYNES® 188 alloy showcases remarkable resistance to the formation of detrimental phases, preserving tensile ductility and impact strength. This exceptional thermal stability outperforms HAYNES® 25 alloy, its predecessor, a testament to the continuous advancement in materials engineering.

HAYNES® 188 alloy, also known as UNS R30188, is engineered to resist oxidizing environments with exceptional efficiency. This characteristic ensures its performance remains consistent and reliable, particularly in applications subjected to prolonged exposures at elevated temperatures.

UNS R30188 alloy offers good fabricability at room temperature, enabling seamless integration into various manufacturing processes. It can be forged, hot-worked, cold-formed, and welded with confidence, allowing for versatility in design and production.

While similar to other solid-solution-strengthened superalloys, HAYNES® 188 alloy demonstrates superior behavior in terms of thermal stability. It minimizes the risk of phase precipitation that could affect critical mechanical properties, offering reliability and longevity in demanding applications.

Raykam Alloys LLP takes pride in maintaining the highest quality standards. Our HAYNES 188 alloy undergoes meticulous quality checks, ensuring that each piece adheres to precise dimensions, surface finish, and structural integrity. With an emphasis on sustainable manufacturing practices, we prioritize not only product excellence but also environmental responsibility.

Elevate your projects with the superior performance of HAYNES 188 alloy. As a leader in alloy manufacturing and distribution, Raykam Alloys LLP is your trusted partner in delivering materials that redefine industry standards. Contact us today to discuss your requirements, explore customization options, and experience the power of innovation with HAYNES® 188 alloy.

Applications of Haynes 188

- Aerospace Components: combustion cans, transition ducts, and critical parts

- Gas Turbine Engines: gas turbine engines, combustion chambers, afterburners, and flame holders

- High-Temperature Environments: excels in applications requiring sustained strength and reliability at temperatures exceeding 2000°F (1095°C).

- Long-Term Durability

- Weight Savings

- Thermal Stability

- Fabrication Versatility

- Diverse Industries

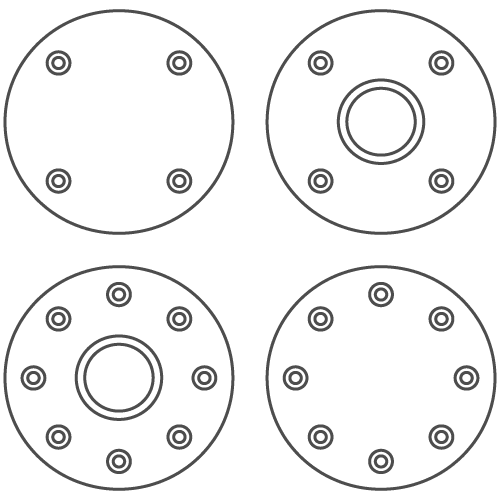

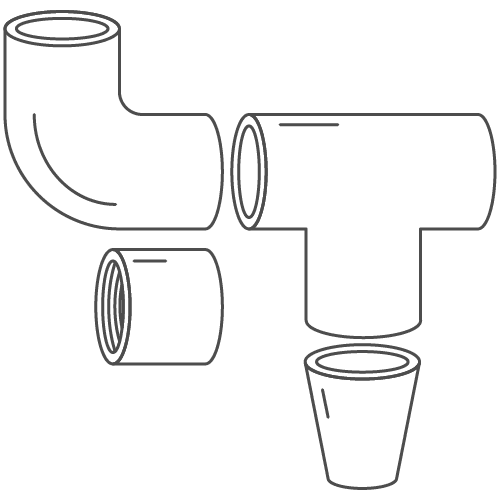

Available Forms