An Overview of Stainless Steel Pipe Fittings: Types and Applications

AN OVERVIEW OF STAINLESS STEEL PIPE FITTINGS: TYPES AND APPLICATIONS

Overview Of This Article

- AN OVERVIEW OF STAINLESS STEEL PIPE FITTINGS: TYPES AND APPLICATIONS

- Introduction To Stainless Steel Pipe Fittings

- Types of Stainless Steel Pipe Fittings

- Stainless Steel 45-Degree Elbows

- Stainless Steel 90-Degree Elbows

- Stainless Steel Street Elbows

- Stainless Steel Tee

- Stainless Steel Reducers

- Stainless Steel Couplings

- Stainless Steel Unions

- Stainless Steel Caps

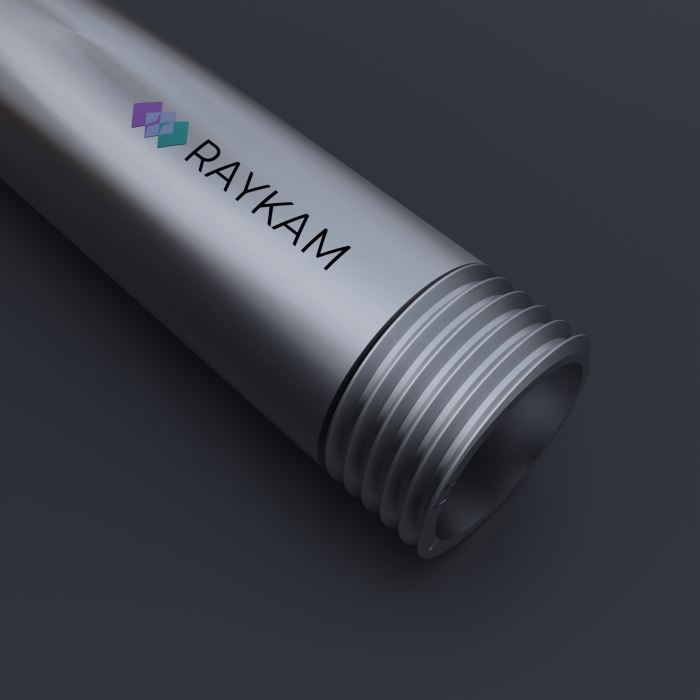

- Stainless Steel Nipples

- Stainless Steel Adapters

- Stainless Steel Flanges

- Stainless Steel Stub Ends

- Stainless Steel Square Head Plugs

- Stainless Steel Round Head Plugs

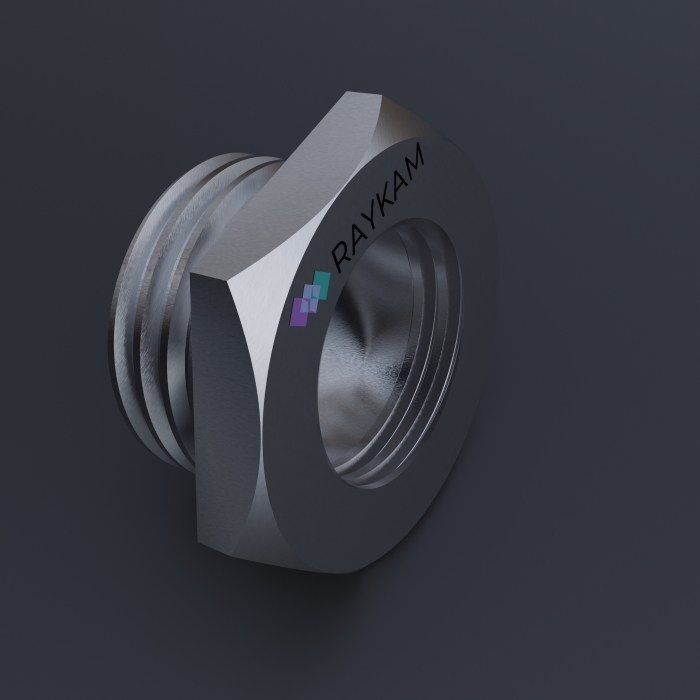

- Stainless Steel Hex Head Plugs

- Stainless Steel 180-Degree Return U Bend

- Stainless Steel Bushings

- Stainless Steel Cross

- Types of Connection Ends for Stainless Steel Pipe Fittings

- Applications of Stainless Steel Pipe Fittings

- Advantages of Using Stainless Steel Pipe Fittings

- Installation and Maintenance Tips For Stainless Steel Pipe Fittings

- Selecting the Right Stainless Steel Pipe Fittings for Your Project

- Understanding Industry Standards for Stainless Steel Pipe Fittings

- An Overview Of Stainless Steel Pipe Fittings: The Conclusion

- THANK YOU

- DON'T MISS ON LATEST ARTICLES!

- MORE RELATED ARTICLES

Introduction To Stainless Steel Pipe Fittings

Welcome to our comprehensive guide on Stainless Steel Pipe Fittings! In this blog post, we will delve into the world of these versatile and essential components that form the backbone of various piping systems across industries. As a top manufacturer in the stainless steel industry, Raykam Alloys LLP takes pride in providing high-quality fittings that ensure leak-free and reliable fluid transportation.

Stainless Steel Pipe Fittings play a pivotal role in connecting, diverting, and controlling the flow of liquids and gases in diverse applications. Their significance lies not only in their ability to facilitate smooth fluid movement but also in their exceptional properties that set them apart from other materials. With excellent corrosion resistance, high strength, and temperature stability, Stainless Steel Pipe Fittings offer a robust solution for even the most demanding industrial environments.

The versatility of Stainless Steel Pipe Fittings is evident in their numerous types, each serving specific purposes in various sectors. From elbows, tees, and reducers to couplings, flanges, and caps, these fittings come in a wide range of shapes, sizes and dimensions compatible with stainless steel pipes, catering to the unique requirements of different projects.

In this comprehensive blog post, we will explore the different types of Stainless Steel Pipe Fittings in detail, examining their applications across industries such as oil and gas, chemical processing, water treatment, HVAC systems, and residential plumbing. We will also shed light on the advantages of using stainless steel fittings in comparison to other materials and delve into the best practices for their installation and maintenance.

Understanding industry standards is crucial in ensuring the reliability and performance of Stainless Steel Pipe Fittings. We will provide insights into the commonly used industry standards that govern the design, manufacturing, and testing of these fittings to ensure their quality and compliance. We will also explore the various types of connection ends available for Stainless Steel Pipe Fittings, including threaded, socket weld, butt weld, flanged, compression, and grooved connections. Each connection type offers unique advantages and is suitable for different installation methods and system requirements.

Whether you are an engineer, contractor, end-user or enthusiast seeking in-depth knowledge about Stainless Steel Pipe Fittings or looking for the right fittings for your project, this blog is your comprehensive resource. At Raykam Alloys LLP, we are committed to providing you with top-notch Stainless Steel Pipe Fittings that meet your specific needs and industry standards.

Stay tuned as we take you on an informative journey through the world of Stainless Steel Pipe Fittings, helping you make informed decisions for your projects and ensuring the success of your fluid transportation systems.

What are Stainless Steel Pipe Fittings?

Stainless Steel Pipe Fittings are crucial components used to connect, control, and direct the flow of fluids in piping systems. Fabricated from premium-grade stainless steel alloys, these fittings offer exceptional strength, durability, and corrosion resistance, making them ideal for a wide range of industrial, commercial, and residential applications.

The versatility of Stainless Steel Pipe Fittings lies in their diverse shapes and designs, enabling them to adapt to various pipe configurations while ensuring secure and leak-free connections. From elbows and tees to caps and couplings, each fitting plays a vital role in optimizing fluid transfer and maintaining the integrity of the overall system.

Importance of Stainless Steel Pipe Fittings in Piping Systems

Stainless Steel Pipe Fittings play a pivotal role in the smooth and efficient operation of piping systems across multiple industries. Their robust construction ensures that they can withstand high-pressure environments, extreme temperatures, and harsh chemical or corrosive substances without compromising structural integrity.

One of the primary advantages of using Stainless Steel Pipe Fittings is their exceptional corrosion resistance. This property is critical, especially in industries such as oil and gas, chemical processing, and water treatment, where exposure to corrosive media is common. The absence of corrosion minimizes maintenance requirements, extends the lifespan of the fittings, and enhances the overall reliability of the system.

Stainless Steel Pipe Fittings provide excellent hygienic properties, making them a preferred choice in industries like food and beverage and pharmaceuticals, where cleanliness and sanitation are paramount. Their non-porous surface prevents bacterial growth and contamination, ensuring the purity and safety of transported fluids.

Types of Stainless Steel Pipe Fittings

Stainless Steel Pipe Fittings have a wide range of types, which when combined with various other options like connectivity ends, size, thickness, type and finishes can unlock a potentially unlimited combination opportunities for your perfect piping systems. Lets explore the most common types of Stainless Steel Fittings.

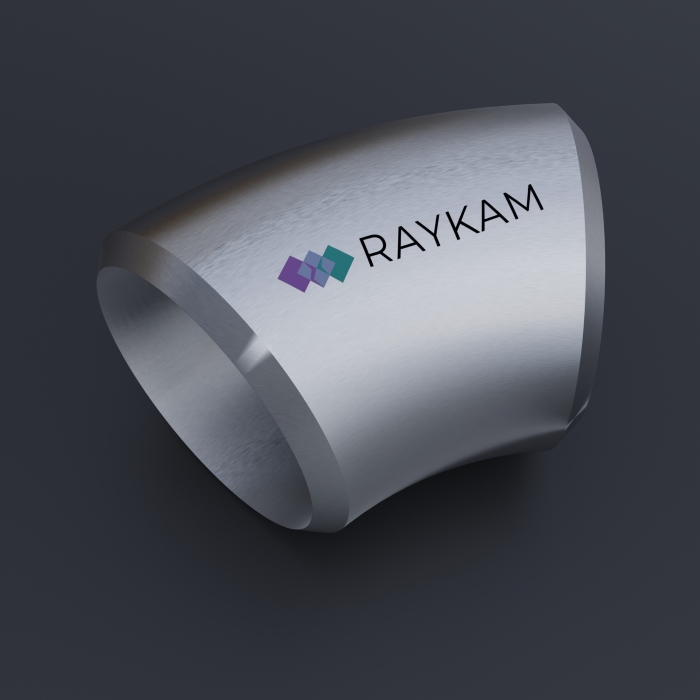

Stainless Steel 45-Degree Elbows

The stainless steel 45-degree elbows are fittings that provide a gentle change in direction within the piping system. They are commonly used in applications where a gradual turn is required to maintain fluid flow and reduce pressure drop. These elbows are versatile and find application in a wide range of industries, including petrochemical, pharmaceutical, and food processing.

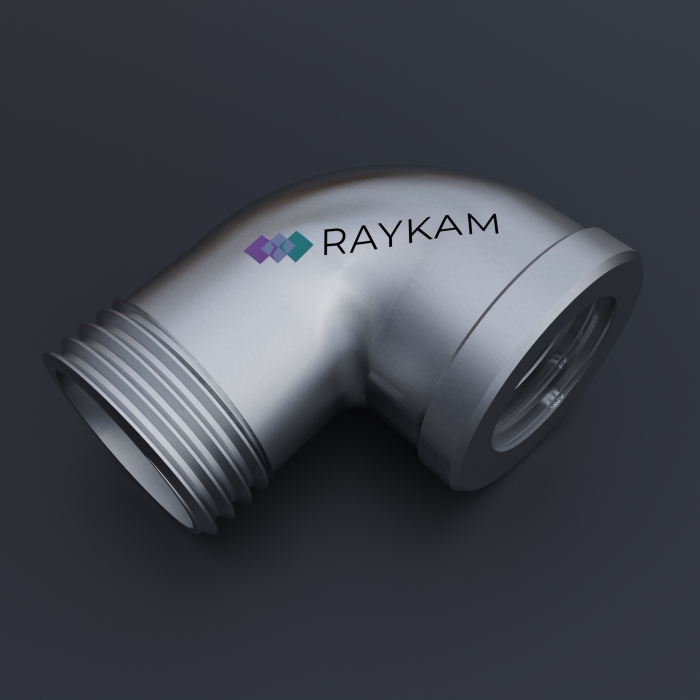

Stainless Steel 90-Degree Elbows

The stainless steel 90-degree elbows are designed to provide a significant turn of 90 degrees within the piping system. They are used when a sharp bend is necessary to redirect the flow of fluids. These elbows are widely used in plumbing, HVAC systems, and industrial processes where precise flow control is essential.

Stainless Steel Street Elbows

Street elbows have one male-threaded end and one female-threaded end. They are commonly used when a change in direction is required between a male-threaded pipe and a female-threaded pipe. Street elbows are particularly useful in residential plumbing and industrial applications where connections with different threading are necessary.

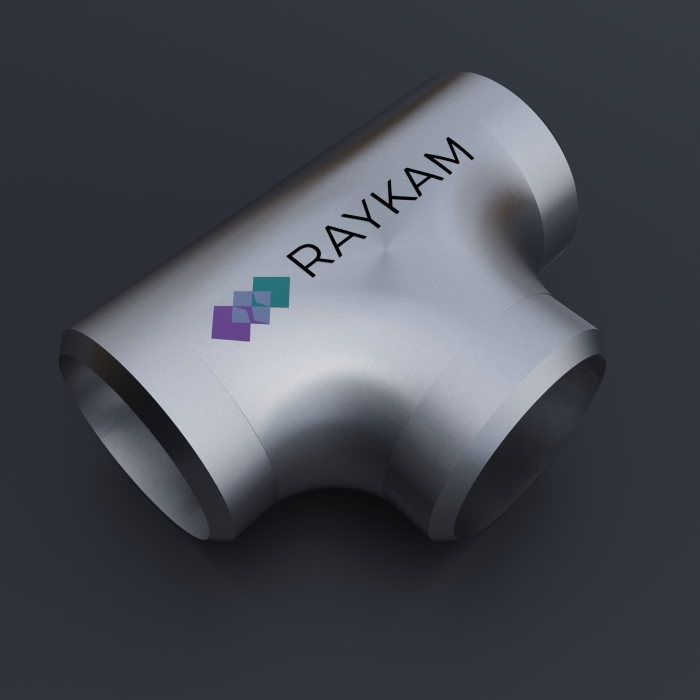

Stainless Steel Tee

Stainless steel tees are T-shaped fittings with three openings used to create a branch within a piping system. They allow for fluid flow in three directions, making them ideal for distributing fluids to multiple locations. Stainless steel tees are available in equal and reducing configurations, with reducing tees featuring different-sized openings to accommodate various pipe sizes.

Stainless Steel Reducers

Stainless steel reducers are fittings used to connect pipes of different diameters, ensuring a smooth transition between sections with varying sizes. Reducers are available in concentric and eccentric designs. Concentric reducers have a symmetrical design, while eccentric reducers have an offset connection to accommodate different centerlines of the connected pipes.

Stainless Steel Couplings

Stainless steel couplings are versatile fittings used to join two pipes of the same size in a straight line. They provide a simple and efficient connection without the need for additional tools or welding. Couplings come in various types, including full couplings that cover the entire pipe end and half couplings that cover only half of the pipe.

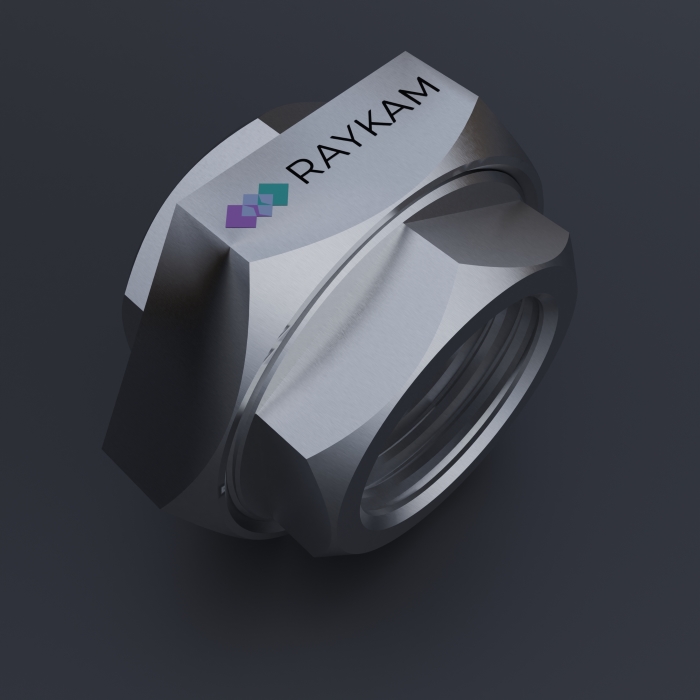

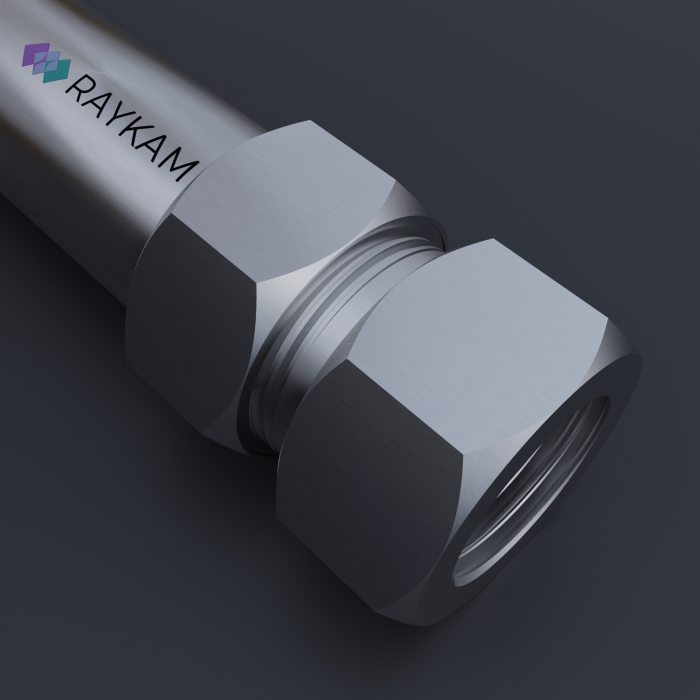

Stainless Steel Unions

Stainless steel unions consist of three parts: a nut, a male end, and a female end. They are designed for ease of installation and disassembly, making them ideal for applications that require periodic maintenance or where sections of the piping system need to be easily disconnected. Unions are available in various sizes and threading configurations to suit different pipe connections.

Stainless Steel Caps

Stainless steel caps are used to close the end of a pipe, providing protection and preventing debris or contaminants from entering the system. They are available in various designs, including threaded, socket weld, and butt weld caps, to accommodate different pipe end connections.

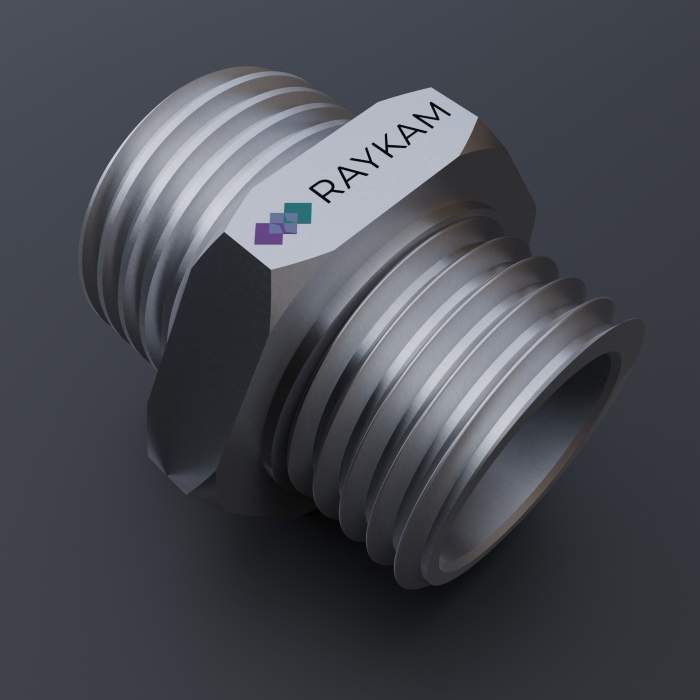

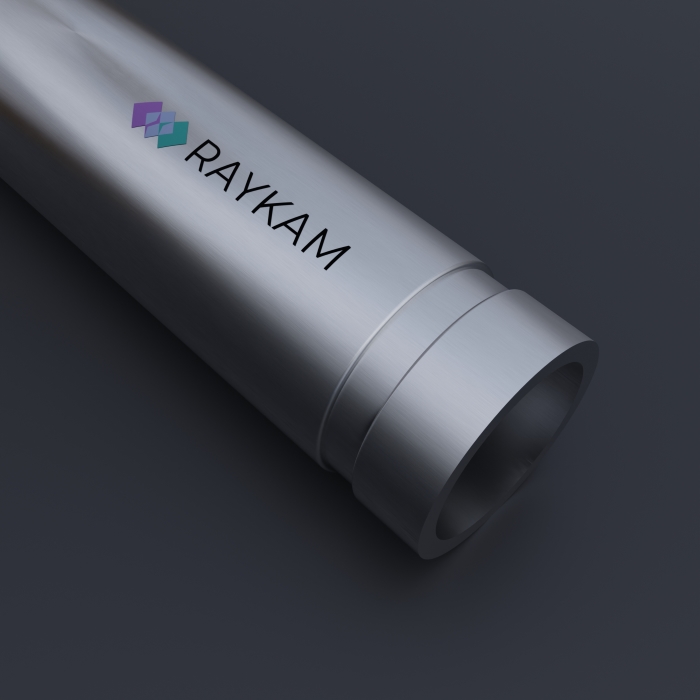

Stainless Steel Nipples

Stainless steel nipples are short lengths of pipe with male-threaded ends on both sides. They are used to extend pipe length or to create a connection between two female-threaded fittings. Stainless steel nipples are available in various lengths and diameters to suit different pipe requirements.

Stainless Steel Adapters

Stainless steel adapters are fittings used to connect different types of pipes or fittings. They provide a seamless transition between different connection methods, such as threaded to socket weld or threaded to butt weld, allowing for greater flexibility in adapting to specific piping needs.

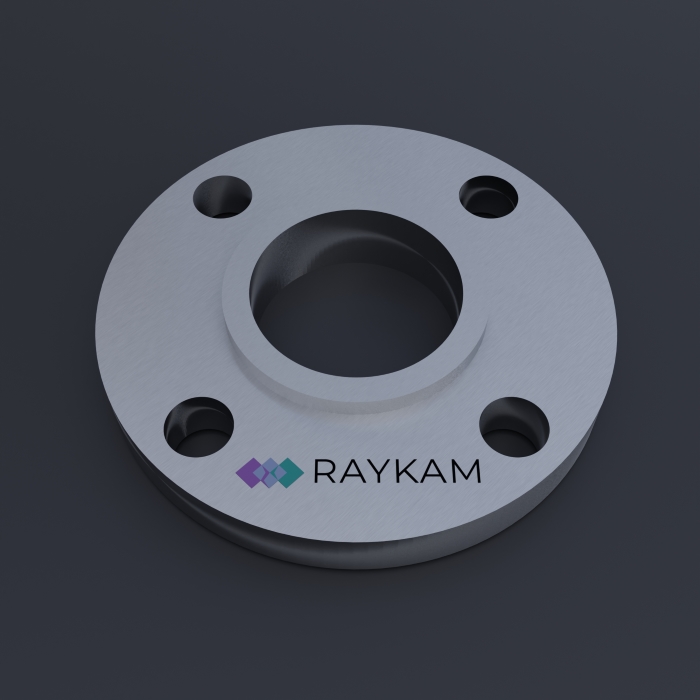

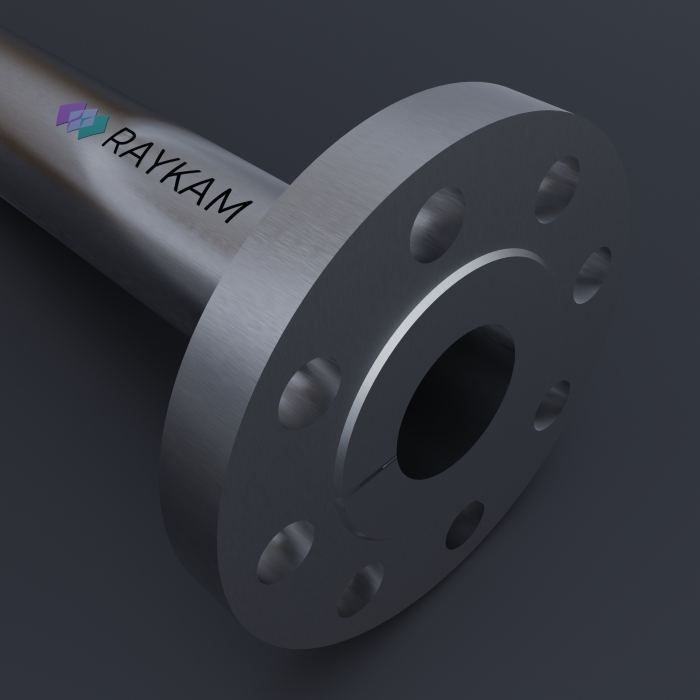

Stainless Steel Flanges

Stainless steel flanges serve as connectors between pipes, valves, or equipment. They provide a secure and leak-proof connection, making them essential components in industries where a reliable and easy-to-assemble joint is required. Stainless steel flanges are available in different types, including slip-on, weld neck, socket weld, and blind flanges, catering to a wide range of application requirements.

Stainless Steel Stub Ends

Stainless steel stub ends are used in conjunction with lap joint flanges to create a tight, yet flexible joint. They allow for rotational alignment when connecting pipes with flanges, making them suitable for applications that require frequent adjustments or pipe alignment.

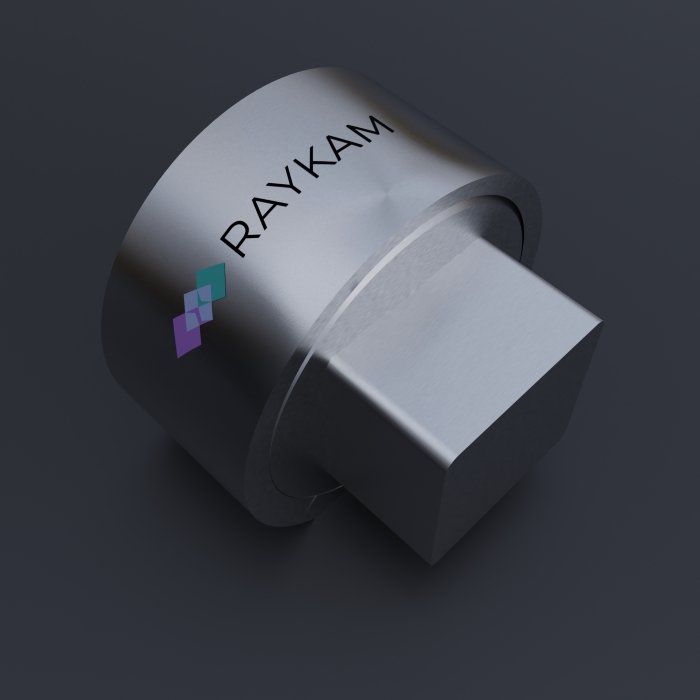

Stainless Steel Square Head Plugs

Stainless steel square head plugs are used to close the end of a pipe and have a square-shaped head for easy gripping during installation and removal. They provide a secure and durable closure, preventing fluid leaks in the system.

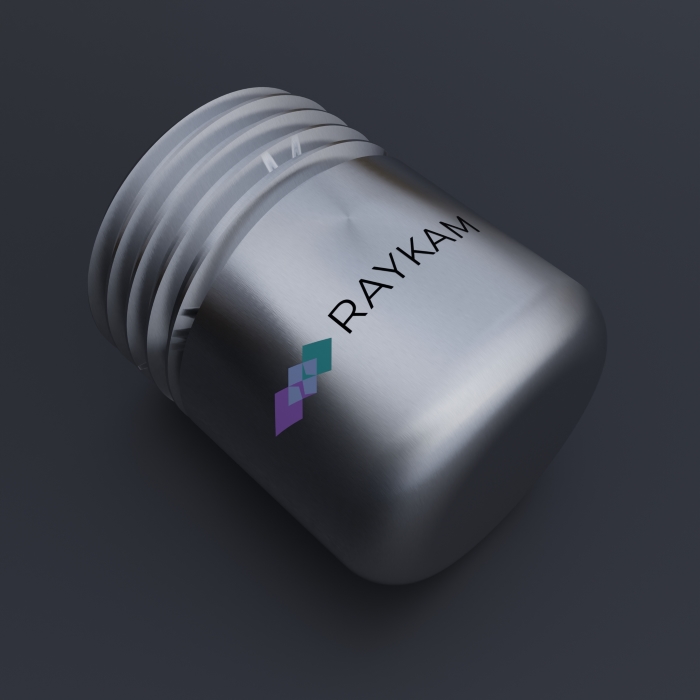

Stainless Steel Round Head Plugs

Stainless steel round head plugs serve the same purpose as square head plugs but have a rounded head for a different aesthetic and functional appeal. They also offer easy installation and removal for closing pipe ends securely.

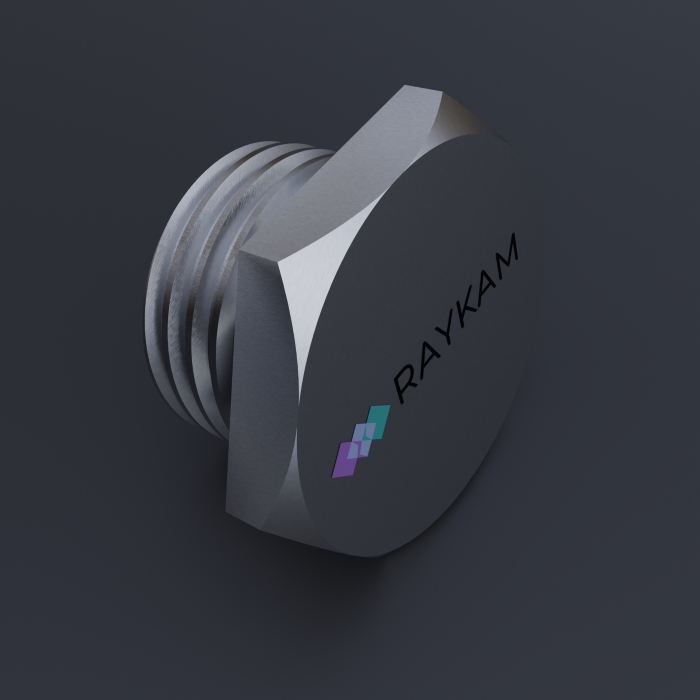

Stainless Steel Hex Head Plugs

Stainless steel hex head plugs have a hexagonal head, providing a secure grip during installation and removal. They are commonly used in applications where a high level of tightness is required, ensuring a reliable seal.

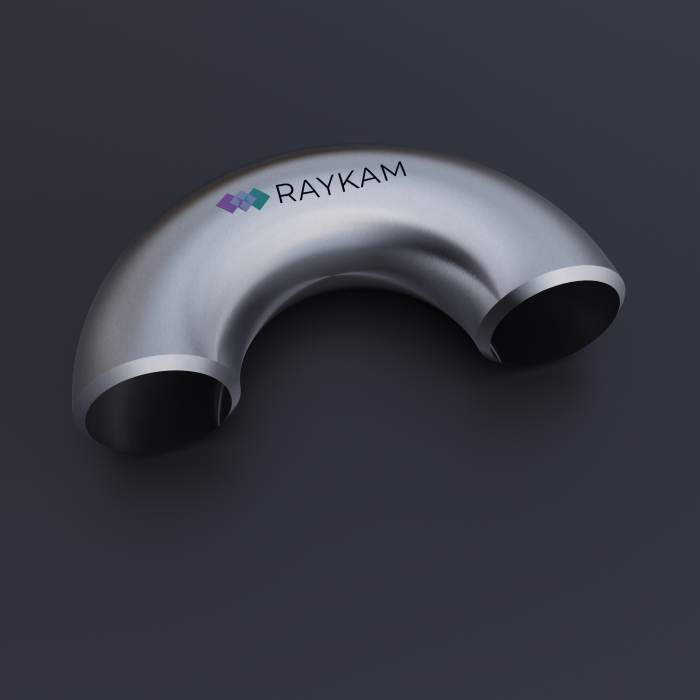

Stainless Steel 180-Degree Return U Bend

Stainless steel 180-degree returns, also known as U-bends, are U-shaped fittings used to change the direction of fluid flow by 180 degrees, effectively reversing the flow within the piping system. They are employed in various applications where a U-shaped bend is necessary for flow control.

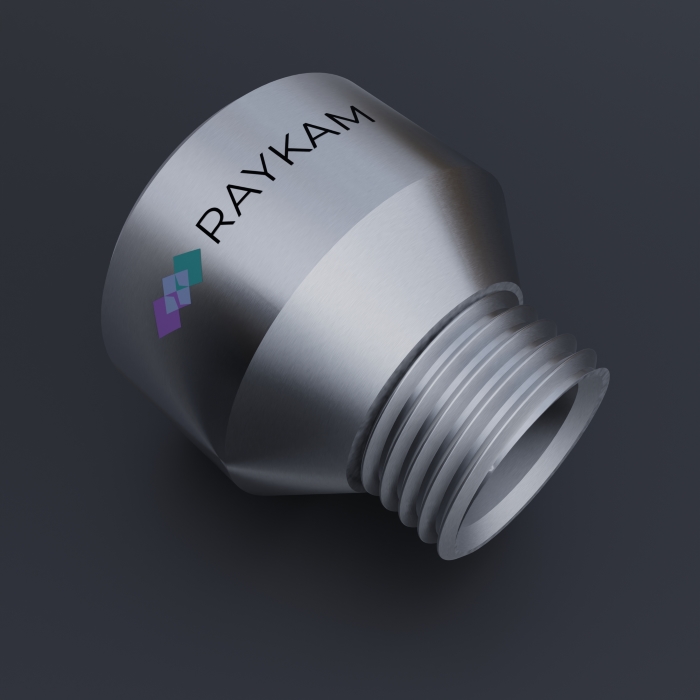

Stainless Steel Bushings

Stainless steel bushings are used to connect pipes of different sizes by reducing the size of the pipe opening. They are commonly used in scenarios where the pipe needs to transition from a larger diameter to a smaller diameter, ensuring a smooth and continuous flow.

Stainless Steel Cross

Stainless steel crosses, also known as four-way fittings, are used to create a branch in a piping system, allowing fluid to flow in four directions. They provide a reliable solution for applications requiring multiple connection points, such as distribution networks and intersection points in complex piping systems.

Types of Connection Ends for Stainless Steel Pipe Fittings

Stainless steel pipe fittings come with different types of connection ends to accommodate various installation methods and piping requirements. Each type of connection offers unique advantages and is suitable for specific applications. Understanding the different connection options is crucial for selecting the right fittings for your project. Below are some commonly used types of connection ends for stainless steel pipe fittings:

Threaded Ends

Threaded ends are one of the most popular types of connection for stainless steel pipe fittings. These fittings have male or female threads on the ends, allowing them to be easily screwed into corresponding threaded pipes or other fittings. Threaded connections are simple to install and disassemble, making them ideal for applications that may require periodic maintenance or adjustments. They are commonly used in low-pressure systems and applications where welding is not desirable or feasible.

Socket Weld Ends

Stainless steel pipe fittings with socket weld ends have a bore on one end that allows the pipe to be inserted directly into the fitting. The connection is then secured by fillet welding the pipe to the fitting on the outside. Socket weld fittings provide a strong and leak-resistant joint, making them suitable for high-pressure and critical applications. They are commonly used in industries such as oil and gas, chemical processing, and petrochemicals.

Butt Weld Ends

Butt weld ends are used in stainless steel pipe fittings designed for permanent and leak-proof connections. The ends of the fitting are beveled for welding, and they are welded directly to the pipes to create a smooth and continuous flow. Butt weld connections provide excellent strength and durability, making them suitable for high-temperature and high-pressure applications. They are commonly used in industries such as power generation, refineries, and shipbuilding.

Flanged Ends

Stainless steel pipe fittings with flanged ends have flat surfaces with bolt holes, allowing them to be bolted directly to flanges on pipes or equipment. Flanged connections are widely used in large-diameter piping systems or applications where easy assembly and disassembly are required. Flanges provide a secure and rigid connection, making them suitable for high-pressure and high-temperature applications in industries such as chemical processing and water treatment.

Compression Ends

Compression ends are commonly used in fittings for connecting tubes or pipes that have an outer diameter. They consist of a compression nut and ferrule that tighten around the pipe when the nut is turned, creating a secure and leak-proof connection. Compression fittings are often used in plumbing systems and applications where a tight seal is essential.

Grooved Ends

Stainless steel pipe fittings with grooved ends are designed for quick and easy installation using grooved couplings. The fittings have grooves on their ends, and the couplings have corresponding grooves, allowing them to be quickly connected by tightening bolts or clamps. Grooved connections are often used in fire protection systems, HVAC systems, and other applications that require fast assembly and disassembly.

Each type of stainless steel pipe fittings connection end offers distinct advantages, and the choice depends on factors such as system design, operating conditions, and installation requirements. At Raykam Alloys LLP, we offer stainless steel pipe fittings with various connection ends to cater to diverse project needs. Our expertise and commitment to quality ensure that you receive fittings that meet the highest standards and deliver reliable performance in your piping systems.

Applications of Stainless Steel Pipe Fittings

Industrial Applications

Oil and Gas Industry

In the oil and gas sector, stainless steel pipe fittings play a crucial role in transporting and processing crude oil, natural gas, and petroleum products. These fittings are used in pipelines, refineries, and offshore platforms, where they must withstand harsh environments, high pressures, and corrosive substances. Their exceptional corrosion resistance ensures reliable performance, minimizing the risk of leaks or failures in critical operations.

Chemical Processing

Stainless steel pipe fittings are widely used in chemical processing plants, where they handle various corrosive and aggressive chemicals. Their resistance to corrosion makes them ideal for conveying acids, solvents, and other chemical compounds. Additionally, stainless steel fittings provide a hygienic solution for handling chemical mixtures used in various industrial processes.

Water Treatement

In water treatment facilities, stainless steel pipe fittings are essential components for handling treated water, wastewater, and various chemicals used in the purification process. The fittings' ability to resist corrosion and maintain water purity is crucial for ensuring the safety and efficiency of water treatment systems.

Commercial Applications

HVAC Systems

Stainless steel pipe fittings are commonly used in heating, ventilation, and air conditioning (HVAC) systems. They facilitate the distribution of heated or cooled air throughout commercial buildings, providing a durable and reliable solution for temperature control. Stainless steel's resistance to rust and corrosion ensures the fittings' longevity, even in demanding commercial environments.

Food and Beverage Industry

In the food and beverage industry, maintaining hygiene and sanitation is of utmost importance. Stainless steel pipe fittings are the preferred choice for food processing plants, breweries, wineries, and dairy facilities due to their non-porous surface and easy-to-clean properties. These fittings prevent bacterial growth and contamination, ensuring the safety and quality of food and beverage products.

Pharmaceutical Industry

The pharmaceutical industry demands high standards of cleanliness and sterility. Stainless steel pipe fittings are widely used in pharmaceutical manufacturing facilities to handle sterile fluids and chemicals. Their smooth surface and corrosion resistance make them suitable for critical applications, ensuring the integrity of pharmaceutical products.

Residential Applications

Plumbing Systems:

In residential plumbing systems, stainless steel pipe fittings provide reliable and leak-free connections for water supply lines, drainage systems, and sewage lines. Their resistance to corrosion and longevity make them an excellent choice for ensuring the integrity of residential plumbing networks.

Household Appliances:

Stainless steel pipe fittings are used in various household appliances, including refrigerators, washing machines, dishwashers, and water heaters. They ensure the efficient flow of water and other fluids within these appliances, contributing to their durability and performance.

Whether in industrial, commercial, or residential settings, stainless steel pipe fittings offer versatile and durable solutions for fluid transportation needs. Their unique properties make them a preferred choice across a wide range of applications, ensuring the reliability and efficiency of piping systems in diverse industries. At Raykam Alloys LLP, we take pride in supplying high-quality stainless steel pipe fittings tailored to meet specific application requirements. Our expertise and commitment to excellence make us the trusted partner for all your stainless steel fitting needs. Experience the difference in performance and durability with Raykam Alloys LLP's top-notch solutions.

Advantages of Using Stainless Steel Pipe Fittings

High Strength and Durability

Stainless steel pipe fittings exhibit exceptional strength, making them highly durable and capable of withstanding high-pressure and high-temperature environments. Their robust construction ensures longevity and reduces the risk of failure, even under demanding conditions.

Corrosion Resistance

One of the most significant advantages of stainless steel pipe fittings is their remarkable corrosion resistance. This property is crucial, especially in industries handling corrosive substances or working in aggressive environments. Stainless steel fittings prevent rusting and corrosion, enhancing the reliability and service life of the entire piping system.

Temperature and Pressure Resistance

Stainless steel pipe fittings are engineered to handle a wide range of temperatures and pressures. They maintain their structural integrity even under extreme conditions, making them suitable for applications in both high-temperature steam systems and cryogenic applications.

Aesthetic Appeal

Beyond their functional advantages, stainless steel pipe fittings also offer aesthetic appeal, making them a popular choice in various architectural and decorative applications. Their clean and polished appearance adds a touch of modern elegance to buildings and facilities.

Low Maintenance

Due to their resistance to corrosion, stainless steel pipe fittings require minimal maintenance. This quality reduces downtime and maintenance costs, making them a cost-effective solution over the long term.

Installation and Maintenance Tips For Stainless Steel Pipe Fittings

Proper installation and regular maintenance are crucial to ensure the optimal performance and longevity of stainless steel pipe fittings. Here are some essential tips to consider during installation and maintenance:

Proper Handling and Storage

During transportation and storage, it is essential to handle stainless steel pipe fittings with care to avoid scratches or damage to the surface. Store them in a dry and clean environment to prevent the accumulation of dirt and moisture, which can lead to corrosion.

Best Practices for Installation

Follow industry best practices and guidelines during the installation process. Ensure that the pipes and fittings are clean and free from any debris or contaminants before assembly. Use appropriate tools and equipment to achieve a secure and leak-proof connection. Avoid over-tightening fittings, as excessive force can lead to thread damage and compromise the integrity of the joint.

Regular Inspection and Maintenance

Implement a regular inspection and maintenance schedule to identify and address any potential issues before they escalate. Check for signs of corrosion, leaks, or loose connections. Replace any damaged or worn-out fittings promptly to maintain the efficiency and safety of the piping system.

Selecting the Right Stainless Steel Pipe Fittings for Your Project

You must be wondering the same thing as all the project managers and piping designers, "How to select the right stainless steel pipe fittings for my project?" or "How to decide which stainless steel pipe fittings to use for my project". Selecting the appropriate stainless steel pipe fittings for your project involves considering several key factors:

Considering Pipe Size and Wall Thickness

Ensure that the fittings you choose are compatible with the pipe size and wall thickness of your piping system. Proper sizing is critical to ensure a secure and leak-free connection.

Understanding Connection Methods

Familiarize yourself with various connection methods, such as threaded, welded, or flanged, and select the one that best suits your specific application and requirements. Each connection method has its advantages and limitations, so make an informed decision based on the intended use and system design.

Compliance with Industry Standards

Always choose stainless steel pipe fittings that comply with relevant industry standards and regulations. This ensures that the fittings meet the necessary quality and performance requirements, providing you with peace of mind and assurance of their reliability.

Understanding Industry Standards for Stainless Steel Pipe Fittings

Stainless steel pipe fittings are subject to various industry standards and specifications to ensure their quality, performance, and compatibility with different piping systems. Adhering to these standards is essential for manufacturers, suppliers, and end-users to achieve uniformity and consistency in product design and application. Below are some of the commonly used industry standards for stainless steel pipe fittings:

ASTM Standards

The American Society for Testing and Materials (ASTM) has established several standards related to stainless steel pipe fittings. ASTM A403 covers wrought austenitic stainless steel pipe fittings for pressure piping applications. ASTM A182 specifies forged or rolled alloy and stainless steel pipe fittings for high-temperature service. These ASTM standards define the material requirements, dimensions, and testing procedures to ensure the suitability of stainless steel fittings for specific operating conditions.

ASME B16 Standards

The American Society of Mechanical Engineers (ASME) has developed several standards under the B16 series that address various aspects of stainless steel pipe fittings. ASME B16.9 covers factory-made wrought butt-welding fittings, while ASME B16.11 focuses on forged fittings, socket-welded, and threaded fittings. ASME B16.5 pertains to pipe flanges and flanged fittings, and ASME B16.25 specifies butt welding ends for piping components. These ASME B16 standards ensure the interchangeability and compatibility of stainless steel pipe fittings in industrial systems.

MSS Standards

The Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry has established various standards for stainless steel pipe fittings. MSS SP-43 covers wrought stainless steel butt-welding fittings, while MSS SP-75 pertains to high-test, wrought, butt-welding fittings. These MSS standards provide guidelines for the design, manufacturing, and testing of stainless steel pipe fittings.

ISO Standards

The International Organization for Standardization (ISO) has developed standards for stainless steel pipe fittings with global applicability. ISO 4144 specifies stainless steel fittings for general purposes, including threaded and socket-welded connections. ISO 3419 defines dimensions for stainless steel butt-welded fittings. These ISO standards promote uniformity in design and ensure the compatibility of stainless steel fittings across different countries and industries.

DIN Standards

The German Institute for Standardization (DIN) has also issued standards for stainless steel pipe fittings. DIN 2605 specifies the dimensions of seamless and welded stainless steel butt-welding fittings, while DIN 2985 covers threaded stainless steel fittings. These DIN standards are widely used in European countries and ensure the quality and reliability of stainless steel fittings.

Compliance with industry standards is crucial for ensuring the safety, performance, and reliability of stainless steel pipe fittings in various applications. At Raykam Alloys LLP, we strictly adhere to industry standards in the manufacturing of our stainless steel pipe fittings, providing our customers with products that meet the highest quality and safety standards.

An Overview Of Stainless Steel Pipe Fittings: The Conclusion

Stainless steel pipe fittings play a crucial role in various industries, providing durable, corrosion-resistant, and reliable solutions for fluid transportation. Their wide range of applications, combined with their outstanding properties, makes them a popular choice for piping systems worldwide. Raykam Alloys LLP offers a comprehensive range of high-quality stainless steel pipe fittings to meet diverse project needs. Our pipe fittings are engineered to deliver exceptional performance, reliability, and longevity, ensuring the success of your projects in industries ranging from oil and gas to food and beverage.

We hope after reading this guide you have learnt all the basics about SS Pipe Fittings. Though learning never ends, we hope this blog post gave you a brief overview about what are stainless steel pipe fittings, how are stainless steel pipe fittings made, how many types of stainless steel pipe fittings are there, what is the important of stainless steel pipe fittings, maintainance and installation of stainless steel pipe fittings, different types end connections of stainless steel pipe fittings, different applications of stainless steel pipe fittings, advantages of using stainless steel pipe fittings, how to select the right stainless steel pipe fitting for your project and understanding industry standards of stainless steel type fittings.

Whether you need fittings for industrial pipelines, commercial HVAC systems, or residential plumbing, our team of experts at Raykam Alloys LLP is here to assist you in selecting the right fittings for your specific requirements. Contact us today to explore our extensive range of stainless steel pipe fittings and take advantage of the benefits they offer for your next project.

At Raykam Alloys LLP, we take pride in being a leading manufacturer of high-quality stainless steel pipe fittings. Our commitment to quality, reliability, and customer satisfaction sets us apart in the industry. When choosing stainless steel pipe fittings for your projects, trust our expertise to deliver top-notch solutions that meet and exceed your expectations.

Explore our extensive catalog of stainless steel pipe fittings, including elbows, tees, reducers, couplings, flanges, and more. Our fittings are fabricated from premium-grade stainless steel alloys, ensuring exceptional performance in even the most demanding applications. Whether you're in the oil and gas sector, chemical processing industry, or require fittings for your residential plumbing needs, we have the right solutions for you.

Our team of experts is dedicated to assisting you in selecting the perfect fittings for your unique requirements. We offer personalized support, technical guidance, and reliable solutions to ensure the success of your projects. Contact us today to discuss your stainless steel pipe fitting needs and experience the quality and reliability that Raykam Alloys LLP brings to the table. Let us be your trusted partner in creating efficient, leak-free, and durable piping systems for your business or residential needs.

THANK YOU

DON'T MISS ON LATEST ARTICLES!

SIGN UP NOW!