Stainless Steel Sanitary Pipes: The Preferred Choice for Hygiene

STAINLESS STEEL SANITARY PIPES: THE PREFERRED CHOICE FOR HYGIENE

Overview Of This Article

- STAINLESS STEEL SANITARY PIPES: THE PREFERRED CHOICE FOR HYGIENE

- Introduction To Stainless Steel Sanitary Pipes

- Applications of Stainless Steel Sanitary Pipes

- Technical Information Of Stainless Steel Sanitary Pipes

- Stainless Steel Sanitary Pipes Grades

- Quality Standards For Stainless Steel Sanitary Pipes

- Available Sizes Of Stainless Steel Sanitary Pipes With Applications

- Stainless Steel Sanitary Pipes, The Preferred Choice for Hygiene: The Conclusion

- THANK YOU

- DON'T MISS ON LATEST ARTICLES!

- MORE RELATED ARTICLES

Introduction To Stainless Steel Sanitary Pipes

Stainless steel sanitary pipes are a critical component in many industries, particularly in the food and beverage, pharmaceutical, and biotech industries. These pipes are designed to meet the high standards of hygiene and cleanliness required in these industries, making them an indispensable part of any production process where purity and cleanliness are a top priority. In this blog article, we'll take a closer look at stainless steel sanitary pipes, their uses, applications, technical information, quality standards, and the different sizes available. We'll also explain why Raykam Alloys LLP is the best choice for supplying this product.

Applications of Stainless Steel Sanitary Pipes

Stainless steel sanitary pipes are used in a wide range of industries where purity and cleanliness are critical, such as food and beverage, pharmaceutical, and biotech industries. They are used to transport various materials, such as liquids, gases, and powders, without contaminating the product. The pipes are specifically designed to meet the high standards of hygiene and cleanliness required in these industries, ensuring that the product is not compromised by contamination.

1) Food and Beverage Industry

In the food and beverage industry, stainless steel sanitary pipes are used to transport various materials, such as water, milk, and juices. They are also used in the production of beer, wine, and other alcoholic beverages. The pipes are designed to meet the strict hygiene and cleanliness standards required by food and beverage production. These pipes are easy to clean and sanitize, ensuring that they meet the high standards of hygiene required in the industry. In the food and beverage industry, the Sanitary Stainless Steel Pipes are also known as Food Grade Stainless Steel Pipes, Stainless Steel Hygienic Pipes, Stainless Steel Dairy Pipes, Stainless Steel Beverage Pipes, etc.

2) Pharmaceutical Industry

In the pharmaceutical industry, stainless steel sanitary pipes are used to transport various chemicals, solvents, and other materials required for the production of medicines. They are also used in the production of medical equipment and devices, such as catheters and syringes. In the pharmaceutical industry, the Sanitary Stainless Steel Pipes are also known as Stainless Steel Pharmaceutical Pipes, Stainless Steel Tubing for Sanitary Applications, Stainless Steel Hygienic Pipes, etc.

3) Biotech Industry

In the biotech industry, SS sanitary pipes are used to transport various materials, such as cell cultures, enzymes, and proteins. They are also used in the production of vaccines and other biotech products. In the biotech industry, the Sanitary Stainless Steel Pipes are also known as Stainless Steel Hygienic Pipes, Stainless Steel Pharmaceutical Pipes, etc.

4) Chemical Processing Industry

In the chemical processing industry, Stainless steel sanitary pipes are ideal for transporting corrosive substances such as acids and chlorides in the chemical processing industry. These pipes are resistant to corrosion and are designed to withstand high temperatures and pressures. In the food and beverage industry, the Sanitary Stainless Steel Pipes are also known as Stainless Steel Tubing for Sanitary Applications, Stainless Steel Pharmaceutical Pipes, etc.

Technical Information Of Stainless Steel Sanitary Pipes

Stainless steel sanitary pipes are typically made from austenitic stainless steel, which contains high levels of chromium and nickel. These materials provide excellent corrosion resistance and are highly resistant to rust and staining. The pipes are also highly durable and can withstand high temperatures and pressures without degrading.

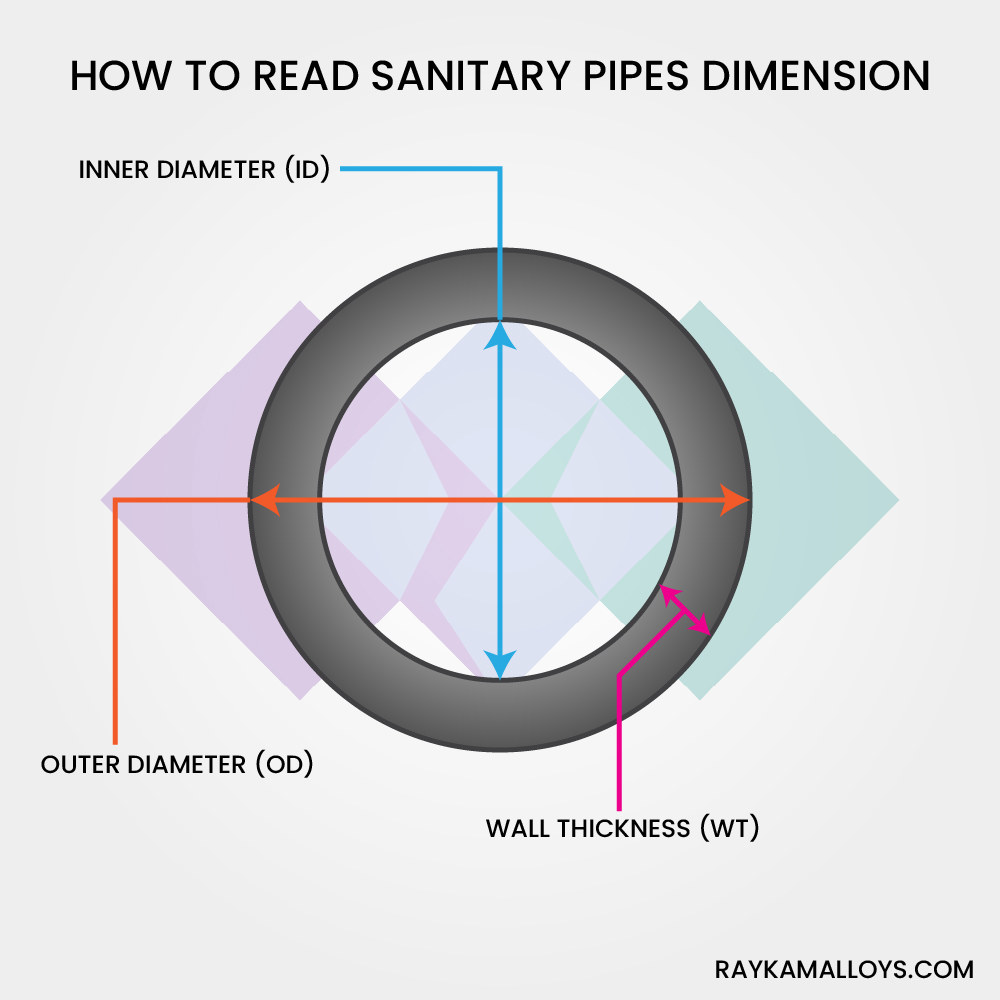

Stainless steel sanitary pipes are available in a variety of sizes, ranging from 1/2 inch to 12 inches in diameter. The wall thickness of the pipes can also vary, depending on the application and the required pressure rating. The pipes are typically polished to a high finish, which makes them easy to clean and maintain.

Sanitary pipes are available in a range of sizes and wall thicknesses to meet the specific needs of various applications. The size and wall thickness of the pipe will determine its strength, durability, and resistance to pressure and temperature changes. Choosing the right size and wall thickness for your specific application is critical to ensuring the safe and efficient operation of your system.

Stainless steel sanitary pipes are typically manufactured using two grades of stainless steel: 304 and 316. Grade 304 stainless steel is a popular choice for its excellent corrosion resistance, while grade 316 stainless steel is preferred in applications where the pipe will be exposed to corrosive substances such as acids and chlorides.

Stainless Steel Sanitary Pipes Grades

Grade 304 stainless steel is the most commonly used grade of stainless steel in the production of sanitary pipes. This grade contains 18% chromium and 8% nickel, which makes it highly resistant to corrosion and oxidation. Grade 304 stainless steel is commonly used in the food and beverage industry, as well as in the dairy industry. This grade is ideal for applications that require high levels of hygiene and cleanliness, as it is easy to clean and sanitize. It is also used in applications that require high strength and corrosion resistance, such as chemical processing.

Grade 316 stainless steel is a higher grade of stainless steel than grade 304. It contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which makes it highly resistant to corrosion and oxidation. Grade 316 stainless steel is preferred in applications where the pipe will be exposed to corrosive substances such as acids and chlorides. Grade 316 stainless steel is commonly used in the pharmaceutical and biotech industries, where purity and cleanliness are critical. This grade is also used in applications that require high strength and resistance to high temperatures and pressures, such as chemical processing.

In addition to grades 304 and 316, there are other grades of stainless steel that are used in the production of sanitary pipes. These include grades 304L, 316L, and 904L.

Grade 304L stainless steel is a low-carbon version of grade 304, which makes it more resistant to sensitization and intergranular corrosion. This grade is often used in applications that involve welding.

Grade 316L stainless steel is a low-carbon version of grade 316, which makes it more resistant to sensitization and intergranular corrosion. This grade is commonly used in the pharmaceutical and biotech industries.

Grade 904L stainless steel is a high-alloy austenitic stainless steel that contains 25% chromium, 4% molybdenum, and 1.5% copper. This grade is highly resistant to corrosion and is often used in applications that involve handling sulfuric acid and other corrosive chemicals.

Quality Standards For Stainless Steel Sanitary Pipes

Stainless steel sanitary pipes are manufactured to strict quality standards to ensure that they meet the hygiene and cleanliness requirements of the industries such as food and beverage, pharmaceutical, and biotech. The SS pipes are typically produced in accordance with international standards such as ASTM A270 and ASME BPE. These standards outline the requirements for the manufacture, testing, and inspection of stainless steel sanitary pipes.

In addition to these standards, Raykam Alloys LLP has implemented a rigorous quality control program to ensure that our products meet the highest standards of quality and performance. Our pipes undergo extensive testing and inspection before they are shipped to our customers, ensuring that they meet all required specifications. We are certified to ISO 9001:2015 quality management system standards, which demonstrates our commitment to quality and continuous improvement.

Available Sizes Of Stainless Steel Sanitary Pipes With Applications

As mentioned earlier, stainless steel sanitary pipes are available in a variety of sizes and wall thicknesses to meet the specific needs of various industries. Here's a closer look at the different sizes available:

- As mentioned earlier, stainless steel sanitary pipes are available in a variety of sizes and wall thicknesses to meet the specific needs of various industries. Here's a closer look at the different sizes available:

- 1/2 Inch (12.7 mm): These pipes are ideal for smaller applications, such as laboratory settings, where space is limited.

- 3/4 inch (19.05 mm): This size is commonly used in the food and beverage industry for transporting liquids and gases.

- 1 inch (24.5 mm): This size is also used in the food and beverage industry, as well as in the pharmaceutical and biotech industries.

- 1-1/2 (38.1 mm): This size is commonly used in larger applications, such as dairy processing and chemical production.

- 2 inch (50.8 mm): This size is ideal for applications that require high flow rates, such as bulk material transfer and wastewater treatment.

- 2-1/2 inch (63.5 mm): This size is commonly used in the pharmaceutical and biotech industries, where purity and cleanliness are critical.

- 3 inch (76.2 mm): This size is used in a variety of applications, including chemical processing, food and beverage production, and water treatment.

- 4 inch (101.6 mm): This size is commonly used in larger applications, such as industrial water treatment and chemical processing.

- 6 inch (152.4 mm): This size is ideal for large-scale industrial applications, such as oil and gas processing and wastewater treatment.

Stainless Steel Sanitary Pipes, The Preferred Choice for Hygiene: The Conclusion

Stainless steel sanitary pipes are a critical component in many industries, particularly in the food and beverage, pharmaceutical, and biotech industries. These pipes are designed to meet the high standards of hygiene and cleanliness required in these industries, making them an indispensable part of any production process where purity and cleanliness are a top priority.

Raykam Alloys LLP is committed to providing high-quality stainless steel sanitary pipes that meet the strictest standards of hygiene and cleanliness. We offer a wide range of sizes and wall thicknesses to meet the specific requirements of our customers. Our products are manufactured to strict quality standards and undergo extensive testing and inspection before they are shipped to our customers.

If you're looking for a reliable supplier of stainless steel sanitary pipes, look no further than Raykam Alloys LLP. We have the expertise, experience, and commitment to quality that you need to ensure that your production processes are not compromised by contamination. Our team of experts can help you select the right size and wall thickness for your specific application, ensuring that you get the most reliable and efficient product for your needs.

In addition to our high-quality products, we also offer exceptional customer service. Our team of customer service professionals is dedicated to ensuring that you get the support you need, from the moment you place your order to the moment your product is delivered. We understand that time is of the essence in many industries, and we work hard to ensure that your order is processed and shipped as quickly as possible.

At Raykam Alloys LLP, we are committed to providing the highest level of quality, reliability, and customer service in the industry. We are confident that we can meet your needs and exceed your expectations, and we look forward to the opportunity to earn your business. Contact us today to learn more about our products and services, and to see how we can help you achieve your production goals.

THANK YOU

DON'T MISS ON LATEST ARTICLES!

SIGN UP NOW!