Monel K-500 | EN 2.4375

NICKEL ALLOYS

Monel K-500 | EN 2.4375

Description

Monel K-500 is a age-hardenable Nickel-Copper alloy which combines the corrosion resistance of Alloy 400 with high strength corrosion fatigue and erosion resistance. It is a nickel-copper alloy, precipitation hardenable through additions of aluminum and titanium. It retains the excellent corrosion resistant characteristics of 400 and has enhanced strength and hardness after precipitation hardening when compared with 400. It has approximately three times the yield strength and double the tensile strength when compared with 400. The alloy can be further strengthened by cold working before the precipitation hardening.

Applications of Monel K-500

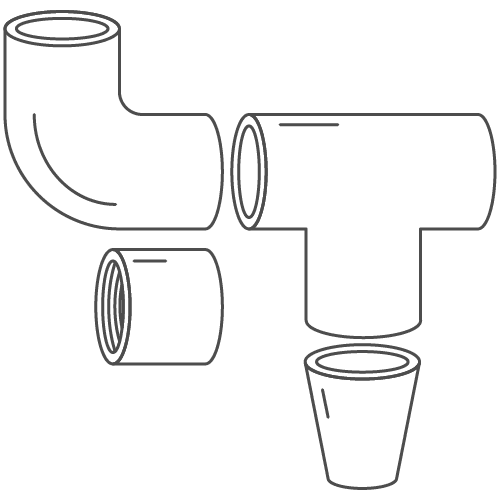

- Propeller Shafts

- Pumps and Valves used in the manufacture of Perchlorethylene, Chlorinated Plastics

- Pump Shafts

- Impellers

- Valve Components for Ships and Offshore Drilling Towers

- Bolting

- Oil Well Drill Collars

- Instrumentation Components for Oil and Gas Production

- Centrifugal Pumps in the Marine Industry

- Offshore oil and gas drilling platforms

- Chemical processing plants

- Marine applications

- Aerospace industry

- Power generation facilities

- Desalination plants

- Pharmaceutical industry

- Petrochemical industry

- Water treatment plants

- Food processing industry

- Pulp and paper mills

- Fertilizer production

- Mining operations

- Industrial waste management facilities

- Renewable energy projects (such as wind farms and solar power plants)

- HVAC (Heating, Ventilation, and Air Conditioning) systems

- Cryogenic applications

- Nuclear power plants

- Semiconductor manufacturing

- Automotive industry (in specific corrosive environments)

- Research laboratories and scientific facilities

- Construction and infrastructure projects (where corrosive environments are present)

Available Forms