EN 1.4122 | X39CrMo17-1

STAINLESS STEEL

EN 1.4122 | X39CrMo17-1

Description

Stainless Steel EN 1.4122, also known as X39CrMo17-1, is a high-carbon martensitic stainless steel. It falls under the category of stainless steels that exhibit excellent hardness, wear resistance, and moderate corrosion resistance. The "EN" in its designation indicates that it is standardized by the European Norm, ensuring its quality and consistency across applications.

One of the defining features of SS EN 1.4122 stainless steel is its high carbon content, typically ranging from 0.33% to 0.55%. This high carbon content contributes to the steel's exceptional hardness, making it well-suited for applications where wear resistance and cutting performance are critical factors.

The alloy also contains chromium, typically comprising 16.00% to 18.00% of its composition. Chromium plays a vital role in enhancing the steel's corrosion resistance, allowing it to withstand exposure to various environments, including mildly corrosive ones. This property is particularly valuable in applications where the steel is exposed to moisture or atmospheric elements, as it helps prevent rust and corrosion.

EN 1.4122 stainless steel contains molybdenum, usually present in the range of 0.80% to 1.30%. Molybdenum contributes to the overall strength and toughness of the steel. It also aids in improving the steel's resistance to pitting and crevice corrosion, further enhancing its suitability for certain challenging environments.

The combination of high carbon, chromium, and molybdenum in EN 1.4122 imparts excellent mechanical properties to the steel. It exhibits a high hardness level, making it suitable for applications where cutting, shearing, or wear resistance is required. Moreover, the steel maintains a certain level of toughness, allowing it to withstand impact and mechanical stresses, albeit to a lesser extent compared to low-carbon stainless steels.

EN 1.4122 stainless steel finds application in various industrial and commercial sectors. One of its prominent uses is in the production of knife blades. Thanks to its high hardness and wear resistance, it is a popular choice among knife manufacturers who seek to create durable and sharp blades.

EN 1.4122 is employed in the manufacturing of surgical instruments. In this context, the steel's corrosion resistance is particularly valuable, as it ensures the longevity and hygienic properties of the instruments during medical procedures.

The alloy is also utilized in bearing and bushing applications. Its hardness and corrosion resistance make it suitable for specific load-bearing components, where the steel can endure friction and wear without significant deformation.

Stainless Steel EN 1.4122 is a versatile and reliable material with a balance of hardness, wear resistance, and moderate corrosion resistance. Its various properties make it a valuable choice in applications that demand cutting performance, durability, and resistance to certain environmental factors. As with any material, proper handling, machining, and heat treatment are essential to optimize its performance and achieve the desired mechanical properties for specific applications.

Raykam Alloys LLP is a reputed supplier, exporter, manufacturers and stockist of EN 1.4122 Grade raw materials. We cater our customers globally with high quality materials, timely deliveries and competitive rates. Superior quality and customer satisfaction are always a priority for us.

Applications of EN 1.4122

- Knife blades

- Surgical instruments

- Bearings and bushings

- Industrial cutting tools

- Shafts and spindles

- Pump components

- Valve components

- Food processing equipment

- Mechanical parts subject to wear

- Precision machinery components

- Textile industry machine parts

- Marine and offshore equipment

- Aerospace components

- Chemical processing equipment

- Automotive components

- Medical devices

- Fasteners and screws

- Sporting and outdoor equipment

- Paper and pulp industry machinery

- Oil and gas industry components

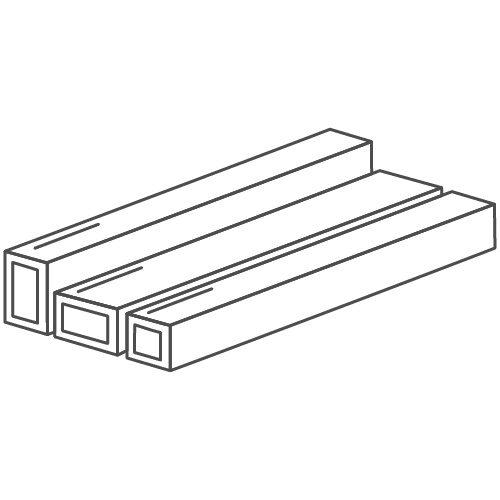

Available Forms