Ti Grade 11 | EN 3.7225

TITANIUM ALLOYS

Ti Grade 11 | EN 3.7225

Description

Titanium Grade 11, also commonly referred to as Titanium Gr 11 or Ti-0.15Pd, is a highly sought-after variation of titanium due to its exceptional corrosion resistance and remarkable strength-to-weight ratio. This titanium alloy belongs to the commercially pure titanium group and contains a small addition of palladium (Pd) to enhance its corrosion resistance, particularly in highly oxidizing environments.

One of the standout features of Titanium Grade 11 is its impressive resistance to corrosion, making it a popular choice for applications in aggressive chemical environments. Its resistance to crevice corrosion and pitting corrosion further enhances its suitability for industries like chemical processing, where materials must withstand corrosive substances and high temperatures.

Ti Grade 11 is also known for its exceptional strength-to-weight ratio, which is higher than that of many other metals. This makes it a favored material in industries such as aerospace and medical, where lightweight yet durable components are crucial for performance and safety. Its low density makes it ideal for applications where weight savings are critical, such as in aircraft components and medical implants.

Apart from its corrosion resistance and strength-to-weight ratio, Titanium Gr 11 offers excellent formability and weldability. This means it can be easily fabricated into various shapes and sizes, allowing manufacturers to meet specific project requirements efficiently.

The biocompatibility makes Titanium Grade 11 a preferred choice for medical implants, such as dental implants, orthopedic devices, and cardiovascular implants. Its ability to integrate seamlessly with the human body and resist corrosion in physiological environments makes it a reliable material for life-saving medical applications.

In summary, Titanium Grade 11 is a versatile and highly desirable titanium alloy known for its exceptional corrosion resistance, impressive strength-to-weight ratio, formability, and biocompatibility. Whether you're in the aerospace, chemical processing, medical, or other industries, Titanium Grade 11 offers a reliable and durable solution for various applications, contributing to advancements in technology, healthcare, and industrial processes.

Applications of Ti Grade 11

- Chemical processing equipment

- Aerospace components

- Medical implants

- Heat exchangers

- Offshore and marine structures

- Electrochemical and desalination plants

- Pollution control equipment

- Automotive parts

- Power generation systems

- Sports equipment

- Marine exhaust systems

- Jewelry and watchmaking

- Architectural structures and cladding

- Oil and gas industry components

- Textile industry machinery

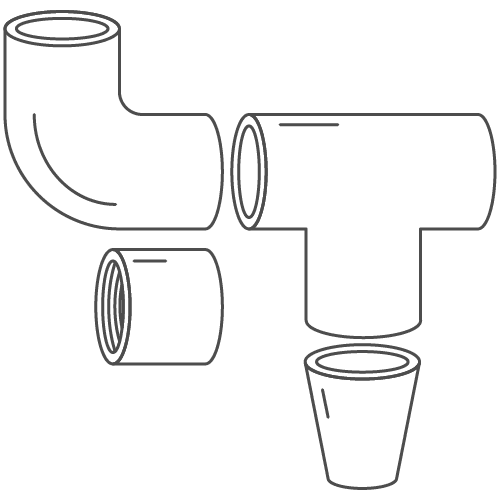

Available Forms