AISI 303 | EN 1.4305

STAINLESS STEEL

AISI 303 | EN 1.4305

Description

Raykam Grade 303 represents the optimum in machinability among the austenitic stainless steels. It is primarily used when production involves extensive machining in automatic screw machines. The machineable nature of this stainless steel grade is due to the presence of Sulphur in the steels composition. Whilst the Sulphur improves machining, it also causes a decrease in the corrosion resistance and a slight lowering of the toughness. The corrosion resistance of this stainless steel grade is lower than that for Stainless Steel 304. The toughness is still excellent as with other austenitic grades. As for other austenitic grades, the structure gives the alloy excellent toughness, although the sulfur in the alloy reduces its toughness slightly.

Stainless Steel 303 is not suitable for use in marine environments. Sulphur additions to the composition act as initiation sites for pitting corrosion. It also offers ease of fabrication compared to other alternative grades available. The alloy has good resistance to oxidation when intermittently exposed to temperatures up to 760°C. It also has good oxidation resistance in continuous service to 870°C. This however, is not recommended as 303 is sensitive to carbide precipitation with continuous use at 425-860°C.

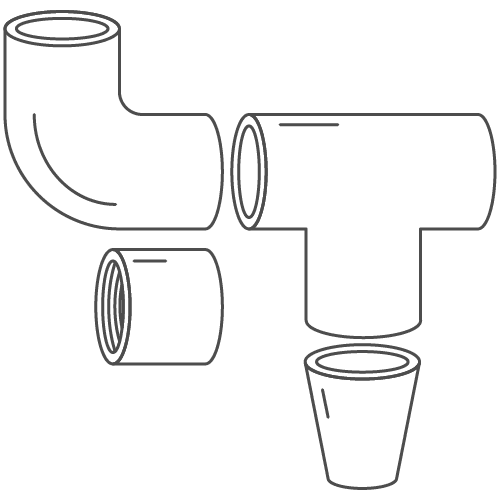

Applications of 303

- Nuts and Bolts

- Bushings

- Shafts

- Aircraft Fittings

- Electrical Switchgear Components

- Electronics Manufacturing

- Gears

- Springs

- Use around chemicals

- Food Production

- In general any component that is heavily machined and where the corrosion resistance and fabrication properties are viable.

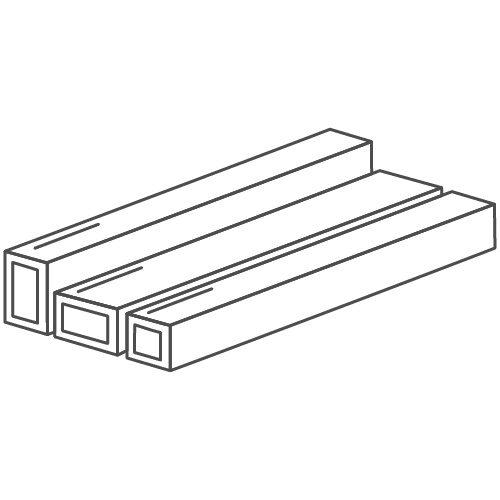

Available Forms